Exploring the Benefits of 3PE Epoxy Coated Steel Pipe Spots in Construction

Apr 29,2025

Exploring the Benefits of 3PE Epoxy Coated Steel Pipe Spots in Construction

Table of Contents

1. Introduction to 3PE Epoxy Coated Steel Pipes

2. Understanding 3PE Coating: What It Is and How It Works

3. Key Benefits of 3PE Epoxy Coated Steel Pipes

3.1 Durability and Longevity

3.2 Corrosion Resistance

3.3 Cost-Effectiveness

3.4 E

Exploring the Benefits of 3PE Epoxy Coated Steel Pipe Spots in Construction

Table of Contents

- 1. Introduction to 3PE Epoxy Coated Steel Pipes

- 2. Understanding 3PE Coating: What It Is and How It Works

- 3. Key Benefits of 3PE Epoxy Coated Steel Pipes

- 3.1 Durability and Longevity

- 3.2 Corrosion Resistance

- 3.3 Cost-Effectiveness

- 3.4 Environmental Sustainability

- 4. Applications of 3PE Epoxy Coated Steel Pipes in Construction

- 5. The Installation Process: Best Practices

- 6. Maintenance and Care for Longevity

- 7. Frequently Asked Questions

- 8. Conclusion

1. Introduction to 3PE Epoxy Coated Steel Pipes

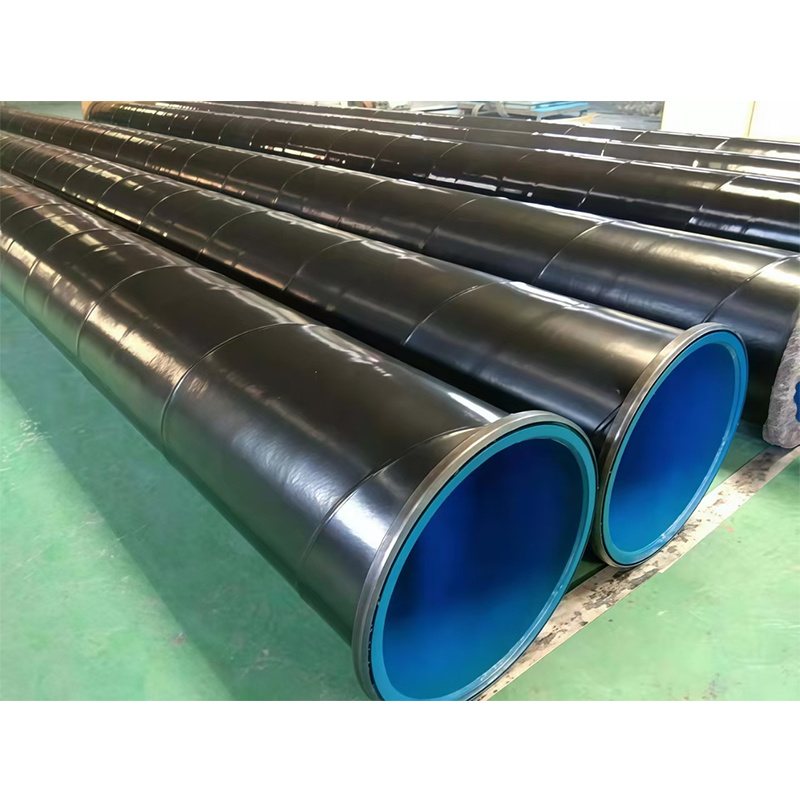

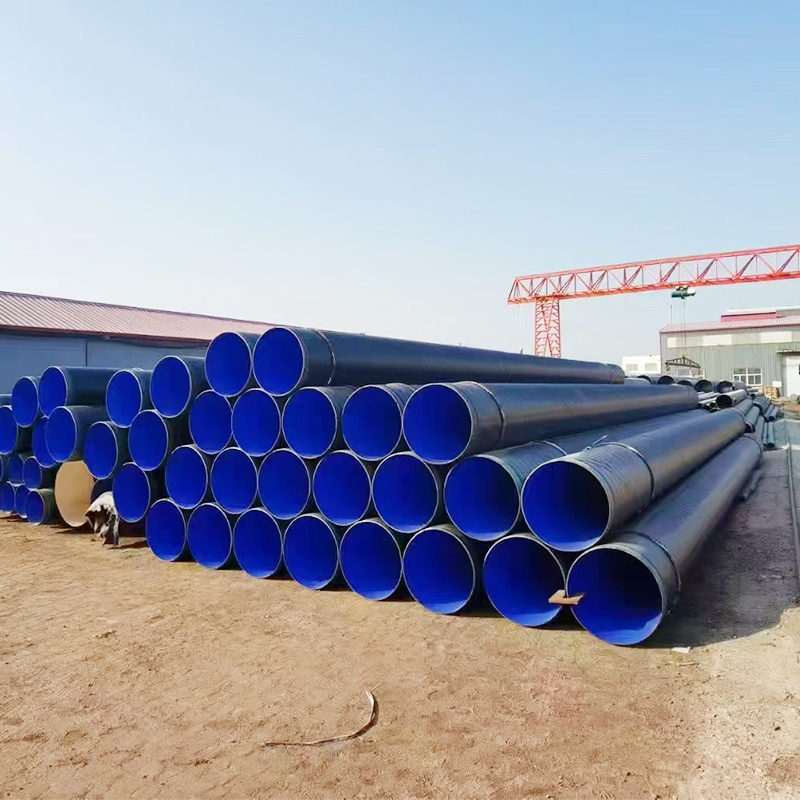

In the realm of construction, the choice of materials can significantly impact the project's overall success. Among the various options available, **3PE epoxy coated steel pipes** have garnered considerable attention due to their remarkable properties. These pipes combine steel's strength with the protective benefits of a specialized three-layer coating system, making them particularly appealing for various construction applications. This article explores the multifaceted benefits of 3PE epoxy coated steel pipes, articulating why they are becoming the go-to solution for contractors and builders worldwide.

2. Understanding 3PE Coating: What It Is and How It Works

The **3PE coating** system comprises three distinct layers, each serving a crucial purpose.

2.1 Composition of 3PE Coating

- **Layer One**: A fusion-bonded epoxy is applied directly to the steel surface. This layer provides excellent adhesion and acts as the primary barrier against corrosion.

- **Layer Two**: A polyethylene layer reinforces the epoxy coating, offering additional protection against physical damage and environmental factors such as moisture.

- **Layer Three**: A top layer of adhesive aids in the bonding of the polyethylene layer to the epoxy, ensuring a durable and resilient finish.

2.2 How 3PE Coating Enhances Pipe Performance

This multi-layered approach not only enhances the structural integrity of the steel pipe but also ensures its longevity by mitigating the risks associated with corrosion, mechanical damage, and environmental stressors.

3. Key Benefits of 3PE Epoxy Coated Steel Pipes

Understanding the **key benefits** of 3PE epoxy coated steel pipes is essential for making informed decisions in construction projects.

3.1 Durability and Longevity

3PE epoxy coated steel pipes are designed to withstand extreme conditions. Their robust structure ensures that they can endure high pressures and physical stresses without compromising integrity. The combined coatings provide a lifespan that significantly surpasses that of uncoated steel pipes, which are susceptible to rust and degradation.

3.2 Corrosion Resistance

Corrosion is one of the leading causes of pipe failure. 3PE coatings offer excellent resistance to a variety of corrosive environments, including chemicals, moisture, and temperature fluctuations. This resistance translates to lower maintenance costs over time and decreased risk of catastrophic pipe failure.

3.3 Cost-Effectiveness

While the initial investment in 3PE epoxy coated steel pipes may be higher than that of standard pipes, the **long-term savings** are substantial. Their durability reduces the need for replacements and repairs, leading to significant cost reductions over the lifespan of a project. Additionally, lower maintenance requirements contribute to overall project efficiency.

3.4 Environmental Sustainability

In an era where sustainability is paramount, **3PE epoxy coated steel pipes** offer a more eco-friendly alternative to traditional options. Their longevity means fewer resources are consumed over time for replacements, and the reduced risk of leaks helps prevent environmental contamination.

4. Applications of 3PE Epoxy Coated Steel Pipes in Construction

The versatility of 3PE epoxy coated steel pipes makes them suitable for a wide range of applications, including:

4.1 Water and Sewage Systems

These pipes are commonly used in water supply and sewage systems due to their corrosion resistance, ensuring safe and reliable delivery.

4.2 Oil and Gas Industry

3PE coatings are critical in the oil and gas sector, where pipes are exposed to harsh chemicals and environmental conditions.

4.3 Structural Applications

In construction, these pipes can be used for structural support, providing both strength and durability.

5. The Installation Process: Best Practices

Proper installation is crucial for maximizing the benefits of 3PE epoxy coated steel pipes.

5.1 Pre-Installation Checks

Before installation, ensure that the pipes are free from damage and defects. Inspect the coating for any blemishes that could compromise performance.

5.2 Installation Techniques

Employ standard practices for pipe installation, including proper alignment and support. Utilize suitable fittings and joints to ensure a leak-free system.

5.3 Post-Installation Inspection

Conduct a thorough inspection following installation to verify the integrity of the joints and the overall system. Monitoring should continue throughout the project's lifespan to ensure ongoing performance.

6. Maintenance and Care for Longevity

While 3PE epoxy coated steel pipes require minimal maintenance, regular inspections can help prolong their lifespan.

6.1 Regular Inspections

Schedule periodic checks for any signs of wear or damage. Early detection can prevent minor issues from becoming major problems.

6.2 Cleaning and Care

Maintain cleanliness around the installed pipes, removing any debris or buildup that could compromise their performance.

7. Frequently Asked Questions

7.1 What is the lifespan of 3PE epoxy coated steel pipes?

With proper installation and maintenance, these pipes can last for several decades, often exceeding 50 years.

7.2 Are 3PE epoxy coated steel pipes suitable for high-pressure applications?

Yes, they are designed to withstand high-pressure environments, making them suitable for various industrial applications.

7.3 Can 3PE epoxy coated pipes be used underground?

Absolutely, their corrosion resistance makes them an excellent choice for underground installations.

7.4 What maintenance do 3PE epoxy coated steel pipes require?

They require minimal maintenance, but regular inspections and cleaning are recommended to ensure longevity.

7.5 Are there any environmental benefits to using 3PE epoxy coated steel pipes?

Yes, their durability leads to less frequent replacements and reduced resource consumption, making them a more sustainable option.

8. Conclusion

In summary, **3PE epoxy coated steel pipes** are revolutionizing the construction industry with their exceptional durability, corrosion resistance, cost-effectiveness, and environmental sustainability. Their versatility in various applications—from water supply systems to structural support—makes them an invaluable asset for contractors and builders. By choosing 3PE coated pipes, you are not only investing in quality and longevity but also contributing to a more sustainable future in construction. As we move forward, embracing innovative materials like 3PE epoxy coated steel pipes will be crucial in enhancing productivity and reducing environmental impact in the construction sector.

TAG:

Related Posts

Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

Table of Contents

1. Introduction to Coated Steel Pipes

2. The Importance of Coated Steel Pipes in Natural Gas Applications

3. Key Advantages of Coated Steel Pipes

3.1 Enhanced Corrosion Resistance

3.2 Increased Longevity and Durability

3.3 Improved Safety Standards

4. Types of Coatings Used in Steel