Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

May 09,2025

Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

Table of Contents

1. Introduction to Coated Steel Pipes

2. The Importance of Coated Steel Pipes in Natural Gas Applications

3. Key Advantages of Coated Steel Pipes

3.1 Enhanced Corrosion Resistance

3.2 Increased Longevity and Durability

3.3 Improved Safety Standards

4. Types of Coatings Used in Steel

Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

Table of Contents

1. Introduction to Coated Steel Pipes

2. The Importance of Coated Steel Pipes in Natural Gas Applications

3. Key Advantages of Coated Steel Pipes

3.1 Enhanced Corrosion Resistance

3.2 Increased Longevity and Durability

3.3 Improved Safety Standards

4. Types of Coatings Used in Steel Pipes

4.1 Polyethylene (PE) Coatings

4.2 Epoxy Coatings

4.3 Polyurethane Coatings

5. Applications of Coated Steel Pipes in the Natural Gas Industry

6. Environmental Impact and Sustainability

7. Market Trends and Future Outlook

8. Frequently Asked Questions (FAQs)

9. Conclusion

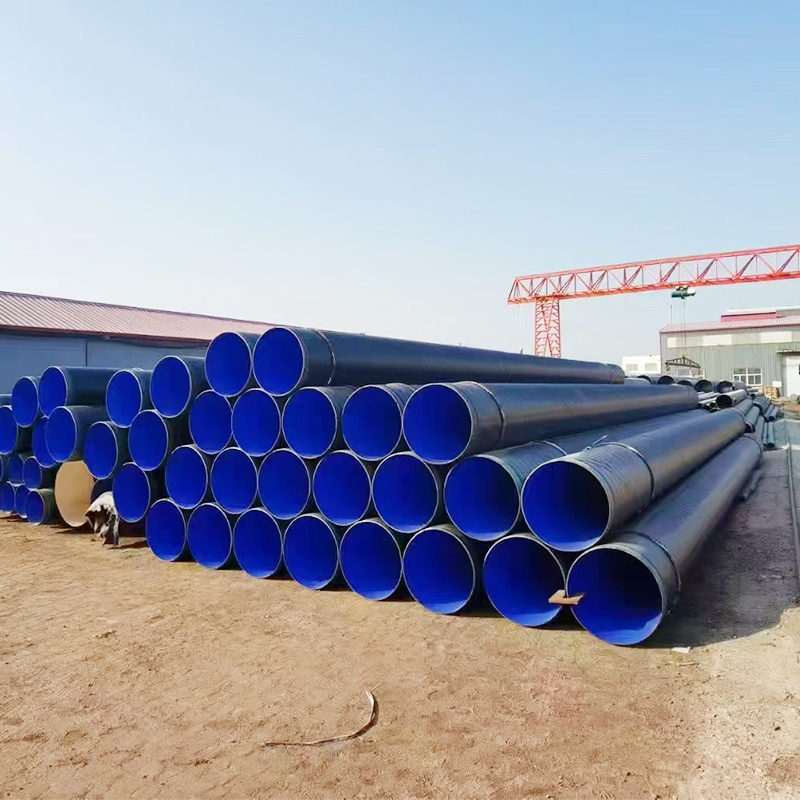

1. Introduction to Coated Steel Pipes

Coated steel pipes play an essential role in various industries, particularly in the energy sector. In China, the rapid growth of the natural gas industry has led to an increased demand for high-quality piping solutions. Coated steel pipes are designed to withstand harsh environmental conditions, ensuring the safe and efficient transport of natural gas. This article explores the numerous benefits of using coated steel pipes in natural gas applications, emphasizing their unique properties and the advancements in coating technologies.

2. The Importance of Coated Steel Pipes in Natural Gas Applications

Natural gas is an increasingly vital energy source in China, contributing to the country’s efforts to reduce carbon emissions and transition to cleaner energy sources. The reliability of the infrastructure used to transport natural gas is crucial to maintaining safety and efficiency. Coated steel pipes are instrumental in this regard as they provide a robust solution that meets stringent industry standards and regulations.

3. Key Advantages of Coated Steel Pipes

Coated steel pipes offer several important benefits that make them the preferred choice for natural gas applications in China.

3.1 Enhanced Corrosion Resistance

Corrosion is a significant concern for any piping system, especially in environments exposed to moisture, chemicals, and extreme temperatures. Coated steel pipes are designed to resist corrosion effectively, prolonging their lifespan and reducing the need for frequent replacements. The protective coating acts as a barrier, preventing corrosive elements from reaching the steel surface.

3.2 Increased Longevity and Durability

The application of protective coatings not only enhances corrosion resistance but also increases the overall durability of the pipes. Coated steel pipes can withstand physical stresses, impact, and wear over time, making them suitable for long-term use in natural gas transportation. This resilience translates into lower maintenance costs and reduced operational disruptions.

3.3 Improved Safety Standards

Safety is paramount in the natural gas sector. Coated steel pipes minimize the risk of leaks, which can have catastrophic consequences. By providing a reliable barrier against external factors, these pipes enhance the safety of natural gas transport, protecting both workers and the environment.

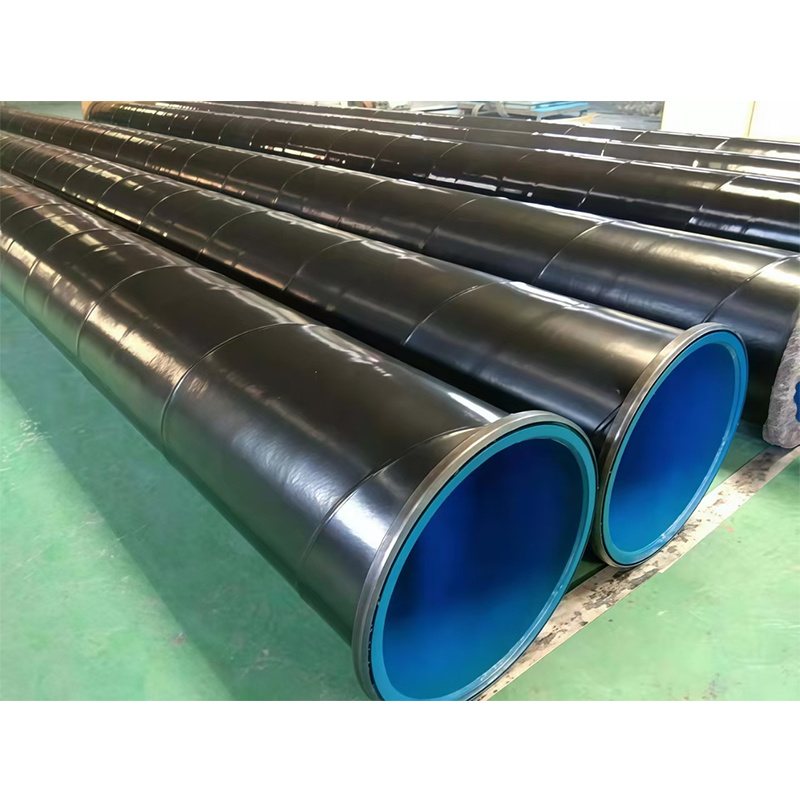

4. Types of Coatings Used in Steel Pipes

The effectiveness of coated steel pipes largely depends on the type of coating applied. Various coatings have unique properties that cater to different environmental conditions and operational requirements.

4.1 Polyethylene (PE) Coatings

Polyethylene coatings offer excellent resistance to moisture and chemicals, making them ideal for underground installations. They are flexible and can accommodate ground movement, reducing the risk of damage during installation and operation.

4.2 Epoxy Coatings

Epoxy coatings provide a hard, durable surface that is highly resistant to abrasion, chemicals, and moisture. They are often used in applications where high mechanical strength is required, ensuring the integrity of the pipes under challenging conditions.

4.3 Polyurethane Coatings

Polyurethane coatings are known for their flexibility and resistance to weathering and UV radiation. They are suitable for above-ground applications where exposure to environmental elements is a concern. Their vibrant colors also serve as a visual cue for maintenance and inspection.

5. Applications of Coated Steel Pipes in the Natural Gas Industry

Coated steel pipes are utilized in various applications within the natural gas industry, including:

- **Transportation of Natural Gas**: These pipes form the backbone of natural gas distribution networks, ensuring efficient delivery from production sites to end-users.

- **Storage Solutions**: Coated steel pipes are used in storage facilities to safeguard natural gas, preventing leaks and contamination.

- **Utility Infrastructure**: Coated steel pipes are essential for utility companies, providing a reliable means of transporting natural gas to residential and commercial consumers.

6. Environmental Impact and Sustainability

The adoption of coated steel pipes in natural gas applications also has positive environmental implications. These pipes contribute to sustainability by:

- **Reducing Leakage**: By minimizing the risk of leaks, coated steel pipes help prevent methane emissions, a potent greenhouse gas, from escaping into the atmosphere.

- **Promoting Recycling**: Steel is one of the most recycled materials in the world. Coated steel pipes can be recycled at the end of their life cycle, reducing waste and promoting circular economy practices.

7. Market Trends and Future Outlook

The market for coated steel pipes in China is expected to grow significantly due to the increasing demand for natural gas and the ongoing investments in infrastructure development. Key trends include:

- **Technological Advancements**: Innovations in coating technologies are leading to more effective and durable solutions, driving the demand for coated steel pipes.

- **Government Regulations**: Stricter safety and environmental regulations are pushing companies to adopt safer and more sustainable piping solutions, further supporting the growth of coated steel pipes.

8. Frequently Asked Questions (FAQs)

**Q1: What are coated steel pipes?**

Coated steel pipes are steel pipes that have been treated with protective coatings to enhance their resistance to corrosion, wear, and environmental factors.

**Q2: Why are coated steel pipes preferred for natural gas applications?**

They offer superior corrosion resistance, increased durability, enhanced safety, and lower maintenance costs, making them ideal for transporting natural gas.

**Q3: What types of coatings are commonly used on steel pipes?**

Common coatings include polyethylene, epoxy, and polyurethane, each offering different properties suitable for various applications.

**Q4: How do coated steel pipes contribute to environmental sustainability?**

By reducing methane leakage and being recyclable, coated steel pipes support sustainable practices within the natural gas industry.

**Q5: What is the future outlook for coated steel pipes in China?**

The market is expected to grow due to increased demand for natural gas, ongoing infrastructure projects, and advancements in coating technologies.

9. Conclusion

In conclusion, coated steel pipes represent a vital component in the natural gas infrastructure of China. Their numerous benefits, including enhanced corrosion resistance, increased durability, and improved safety standards, make them the preferred choice for transporting natural gas. As the industry continues to evolve, the adoption of coated steel pipes will play a crucial role in ensuring the safe and efficient delivery of this essential resource. Investing in these advanced materials not only supports the current demands of the energy sector but also aligns with sustainable practices that benefit the environment.

TAG:

Related Posts

Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

Table of Contents

1. Introduction to Coated Steel Pipes

2. The Importance of Coated Steel Pipes in Natural Gas Applications

3. Key Advantages of Coated Steel Pipes

3.1 Enhanced Corrosion Resistance

3.2 Increased Longevity and Durability

3.3 Improved Safety Standards

4. Types of Coatings Used in Steel