The Essential Role of Coatings in Safeguarding Industrial Painted Steel Pipes

May 03,2025

The Essential Role of Coatings in Safeguarding Industrial Painted Steel Pipes

Table of Contents

Introduction to Coatings and Industrial Steel Pipes

Why Coatings Are Crucial for Steel Pipes

Types of Protective Coatings for Industrial Steel Pipes

Epoxy Coatings

Polyurethane Coatings

Zinc-Based Coatings

Application Methods for Coa

The Essential Role of Coatings in Safeguarding Industrial Painted Steel Pipes

Table of Contents

- Introduction to Coatings and Industrial Steel Pipes

- Why Coatings Are Crucial for Steel Pipes

- Types of Protective Coatings for Industrial Steel Pipes

- Application Methods for Coatings

- Maintenance of Coated Steel Pipes

- Case Studies: Successful Coating Applications

- Future Trends in Coating Technologies

- FAQs

- Conclusion

Introduction to Coatings and Industrial Steel Pipes

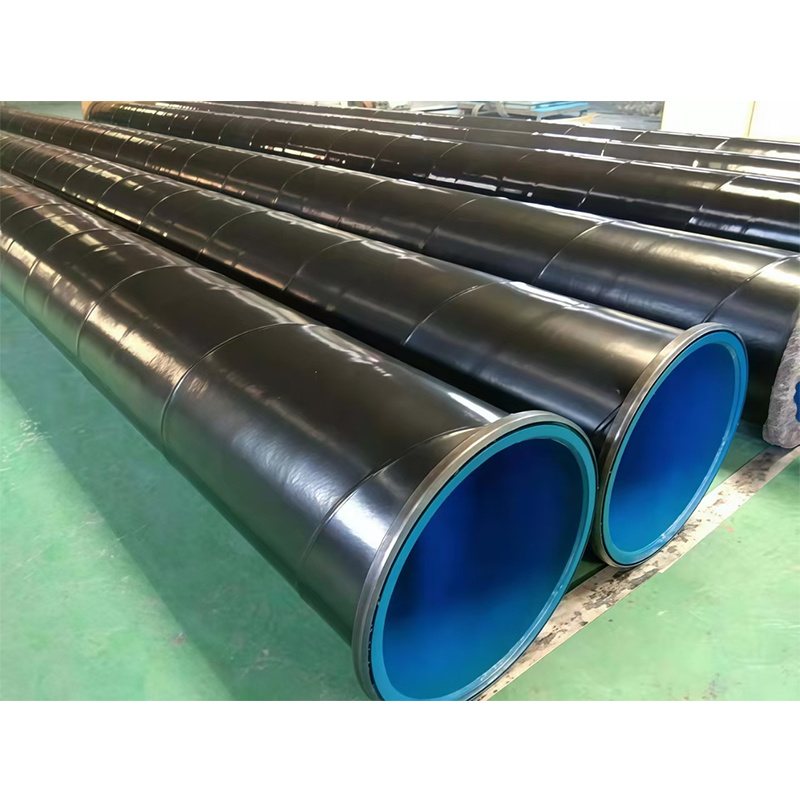

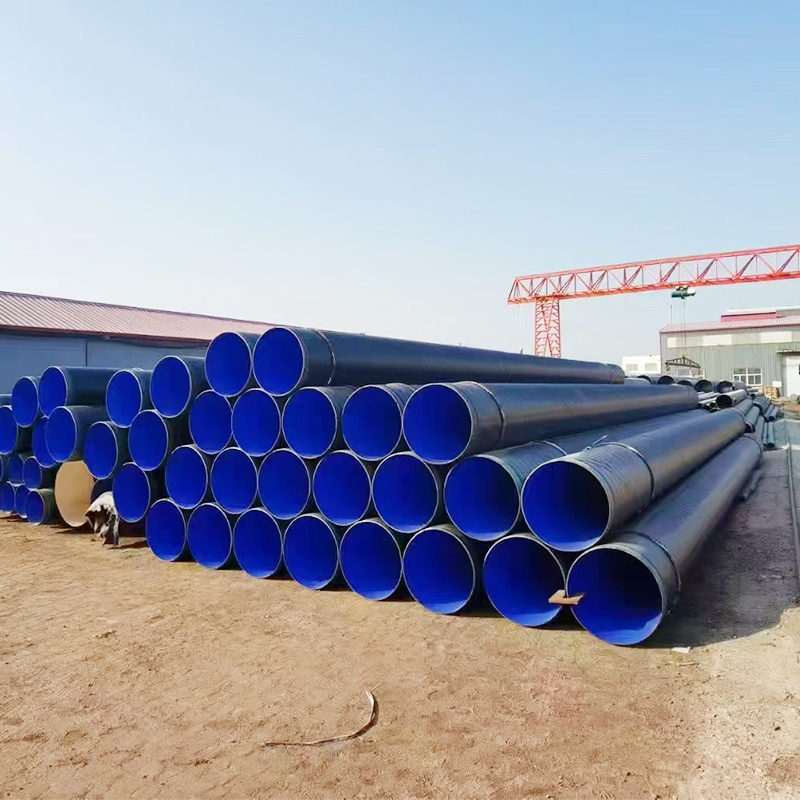

In the industrial sector, **painted steel pipes** serve as integral components in various applications, from construction to infrastructure. However, **unprotected steel pipes** are susceptible to numerous threats, including **corrosion**, mechanical wear, and environmental damage. This is where **protective coatings** play a pivotal role. By applying a proper coating, we can significantly enhance the durability and longevity of steel pipes, ensuring they withstand demanding conditions.

Why Coatings Are Crucial for Steel Pipes

The significance of **coatings** in safeguarding industrial painted steel pipes cannot be overstated. Here are several reasons why coatings are essential:

1. Corrosion Resistance

Corrosion is one of the leading causes of steel pipe degradation. Protective coatings create a barrier that prevents moisture and other corrosive agents from coming into contact with the steel surface, significantly prolonging the life of the pipes.

2. Enhanced Durability

Coatings improve the mechanical strength of steel pipes. They can withstand abrasions, impacts, and environmental stresses, making them ideal for industrial applications where pipes are exposed to harsh conditions.

3. Aesthetic Appeal

Although functionality is paramount, aesthetics matter too. Coatings can enhance the appearance of steel pipes, providing a clean and polished look that can be vital in certain applications, such as visible infrastructure.

4. Thermal Protection

Some coatings provide thermal insulation, helping regulate temperature fluctuations within the pipes and protecting the integrity of the materials contained within.

Types of Protective Coatings for Industrial Steel Pipes

Different types of coatings serve various purposes and environments. Understanding these options can help in selecting the right coating for specific applications.

Epoxy Coatings

Epoxy coatings are known for their robust adhesion and excellent chemical resistance. They are often used in environments where pipes are exposed to harsh chemicals and solvents. The two-component system typically consists of a resin and a hardener, providing a tough and durable finish.

Polyurethane Coatings

Polyurethane coatings offer exceptional UV resistance and maintain their color and gloss over time. These coatings are ideal for outdoor applications where exposure to sunlight and weather can deteriorate other types of finishes.

Zinc-Based Coatings

Zinc-based coatings, such as galvanization, provide sacrificial protection to steel pipes. The zinc layer corrodes preferentially, shielding the underlying steel from corrosion. This coating is widely used in environments prone to moisture and corrosive substances.

Application Methods for Coatings

Proper application of protective coatings is critical to their effectiveness. There are several methods, each with its own advantages and best-use scenarios.

Spray Application

Spray application is one of the most common methods, allowing for an even coat over large areas. This technique is efficient for both large and small projects and can be adapted for different types of coatings.

Brush and Roller Application

For smaller projects or touch-ups, brush and roller application can be effective. This method provides greater control over the thickness of the coating and is suitable for areas that may be difficult to reach with a sprayer.

Powder Coating

Powder coating is an advanced technique where dry powder is applied electrostatically and then cured under heat. This results in a hard, durable finish that is resistant to chipping, scratching, and fading, making it ideal for outdoor applications.

Maintenance of Coated Steel Pipes

Even the best coatings require maintenance to ensure their longevity. Regular inspections for signs of wear, damage, or corrosion are essential in maintaining the integrity of painted steel pipes.

1. Regular Inspections

Conducting periodic inspections allows for the early identification of any issues. Look for signs of corrosion, peeling, or discoloration, which may indicate the need for recoating.

2. Cleaning

Keep the surface of the pipes clean from dirt, debris, and chemical residues. Regular cleaning can prolong the life of the coating and the pipe itself.

3. Repairing Damage

Promptly address any damage to the coating. Small repairs can prevent larger problems and extend the life of the pipes.

Case Studies: Successful Coating Applications

Several organizations have successfully implemented protective coatings on their industrial painted steel pipes, resulting in enhanced performance and longevity.

Case Study 1: Oil and Gas Industry

A major oil and gas company faced challenges with corrosion on their steel pipelines. By applying a high-quality epoxy coating, they significantly reduced maintenance costs and extended the lifespan of their pipes.

Case Study 2: Water Treatment Facilities

A water treatment facility utilized zinc-based coatings on their steel pipes, achieving remarkable resistance to corrosion in a highly corrosive environment. This led to an increase in operational efficiency and reduced downtime.

Future Trends in Coating Technologies

As technology advances, so do the methods and materials used in protective coatings. Emerging trends include:

1. Nanotechnology

Nanotechnology is paving the way for coatings that offer superior protection with thinner applications. These advanced coatings can provide enhanced resistance to scratches and chemicals.

2. Smart Coatings

Smart coatings equipped with sensors can monitor the condition of the pipe and alert operators to potential issues before they become significant problems.

3. Sustainable Coating Solutions

The industry is moving toward more sustainable and eco-friendly coatings, focusing on reducing environmental impact while maintaining high performance.

FAQs

1. What types of coatings are best for protecting steel pipes?

The best coatings depend on the application. Epoxy, polyurethane, and zinc-based coatings are popular choices, each offering specific benefits.

2. How often should I inspect coated steel pipes?

Regular inspections should be conducted at least once a year, or more frequently in harsh environments.

3. Can I reapply a coating over an existing one?

Yes, but proper surface preparation is essential. Ensure that the existing coating is still intact and adheres well before applying a new layer.

4. Are there eco-friendly coating options available?

Yes, there are several eco-friendly coatings available that minimize environmental impact while providing effective protection.

5. How can I tell if my coating is failing?

Signs of failure include peeling, discoloration, or the appearance of rust or corrosion. Regular inspections can help identify these issues early.

Conclusion

In conclusion, the role of coatings in protecting industrial painted steel pipes is indispensable. By enhancing durability, providing corrosion resistance, and ensuring aesthetic appeal, coatings contribute significantly to the longevity and performance of steel pipes in various industrial applications. As technology advances, the future of protective coatings looks promising, with more effective and sustainable solutions on the horizon. Investing in high-quality coatings and proper maintenance practices will ensure that industrial painted steel pipes remain resilient and reliable for years to come.

TAG:

Related Posts

Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

Table of Contents

1. Introduction to Coated Steel Pipes

2. The Importance of Coated Steel Pipes in Natural Gas Applications

3. Key Advantages of Coated Steel Pipes

3.1 Enhanced Corrosion Resistance

3.2 Increased Longevity and Durability

3.3 Improved Safety Standards

4. Types of Coatings Used in Steel