Why Choosing the Best Painted Galvanized Steel Pipe is Crucial for Your Construction Project

May 05,2025

Why Choosing the Best Painted Galvanized Steel Pipe is Crucial for Your Construction Project

When embarking on a construction project, selecting the right materials is paramount to ensuring the longevity and effectiveness of the structure. Among various options available, **painted galvanized steel pipes** stand out for their remarkable durability, corrosion resistance, and aesthetic appeal. This

Why Choosing the Best Painted Galvanized Steel Pipe is Crucial for Your Construction Project

When embarking on a construction project, selecting the right materials is paramount to ensuring the longevity and effectiveness of the structure. Among various options available, **painted galvanized steel pipes** stand out for their remarkable durability, corrosion resistance, and aesthetic appeal. This article delves into the essential factors related to the selection and use of painted galvanized steel pipes, providing you with insights to make informed decisions for your construction endeavors.

Table of Contents

- Understanding Galvanized Steel Pipes

- Advantages of Painted Galvanized Steel Pipes

- Applications in Construction

- Key Factors in Choosing the Right Pipe

- Installation Guidelines for Painted Galvanized Pipes

- Maintenance Best Practices

- Cost Considerations

- Frequently Asked Questions

Understanding Galvanized Steel Pipes

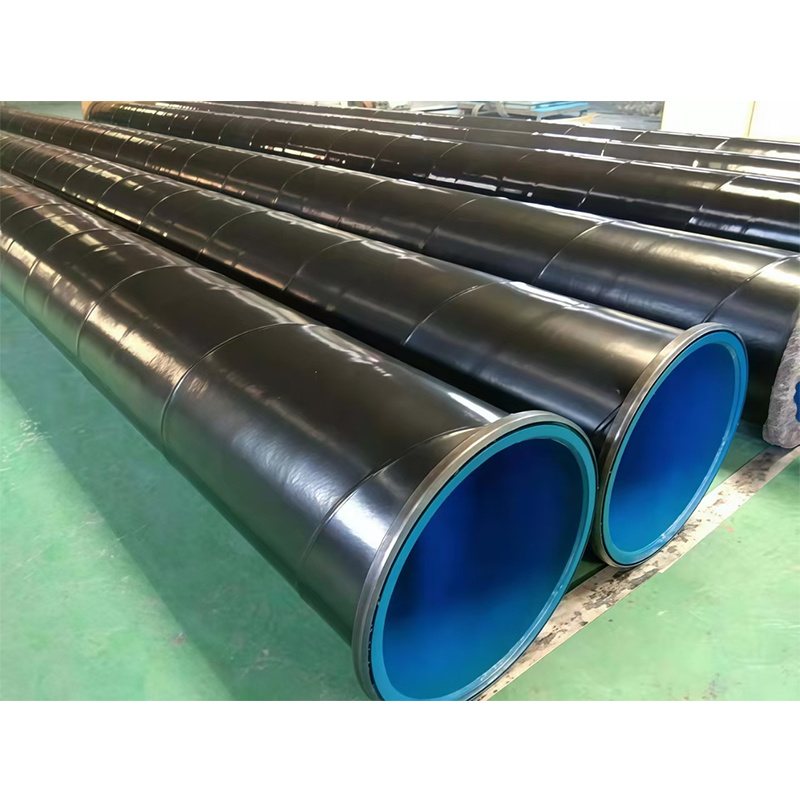

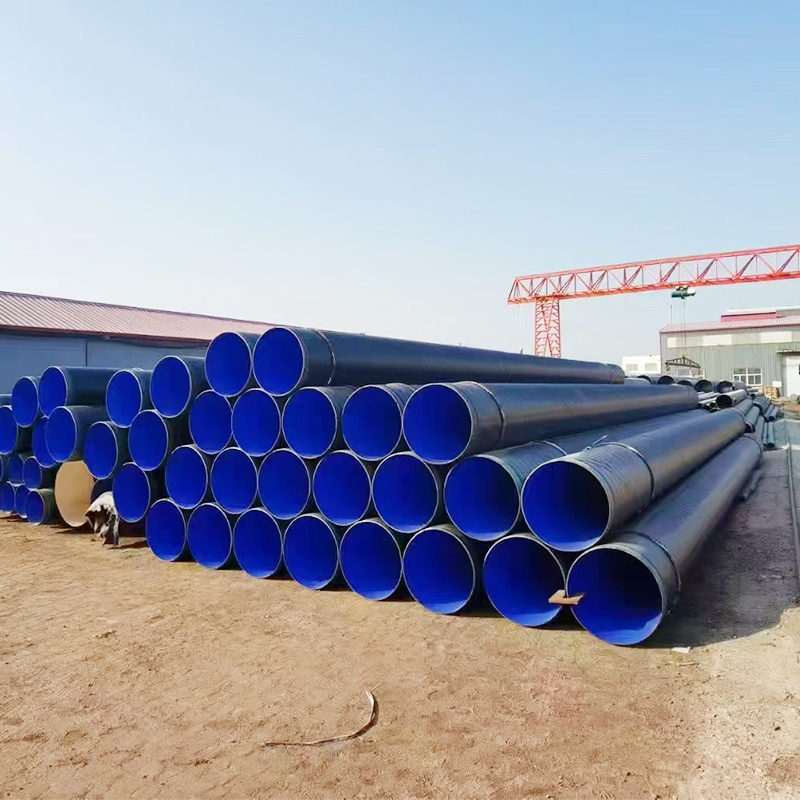

Galvanized steel pipes are steel pipes that have undergone a protective coating process known as galvanization. This process involves dipping the steel in molten zinc, which forms a protective layer that prevents rust and corrosion. The **painted variant** further enhances these properties by adding an additional layer of paint, which not only improves aesthetics but also provides extra protection against environmental factors.

Advantages of Painted Galvanized Steel Pipes

The use of painted galvanized steel pipes in construction offers numerous advantages:

Corrosion Resistance

The primary benefit of galvanized steel is its impressive resistance to rust and corrosion, making it suitable for a variety of environments, including industrial and outdoor settings.

Durability

These pipes are known for their strength and ability to withstand heavy loads and harsh conditions, ensuring that your construction project is built to last.

Aesthetic Appeal

The **painted finish** provides an attractive appearance, allowing you to choose colors that complement your project's design, which is especially important for visible structural elements.

Cost Efficiency

While the initial investment may be higher than non-galvanized options, the long-term savings from reduced maintenance and replacement costs make painted galvanized steel pipes a cost-effective choice.

Applications in Construction

Painted galvanized steel pipes can be utilized in various applications throughout the construction process, including:

Plumbing Systems

These pipes are commonly used in plumbing systems, where their corrosion resistance helps prevent leaks and water damage.

Structural Support

In many cases, painted galvanized steel pipes are used as structural supports in buildings, providing strength and stability.

Fencing and Railings

The attractive finish makes them ideal for fencing and railings, enhancing both safety and aesthetics.

HVAC Systems

In HVAC installations, these pipes are used for ductwork, where durability and resistance to corrosion are vital.

Key Factors in Choosing the Right Pipe

When selecting painted galvanized steel pipes for your construction project, consider the following factors:

Pipe Diameter and Thickness

The size and thickness of the pipe play a significant role in its application and strength. Ensure you choose the correct specifications based on the intended use.

Quality of Coating

Not all galvanized pipes are created equal. Investigate the quality of the galvanization and paint to ensure it meets industry standards.

Supplier Reputation

Choose a reputable supplier with positive reviews and proven experience in providing high-quality materials.

Compliance with Standards

Ensure that the pipes comply with local building codes and industry standards to guarantee safety and reliability.

Installation Guidelines for Painted Galvanized Pipes

Proper installation is crucial to maximizing the benefits of painted galvanized steel pipes. Follow these guidelines:

Preparation and Cleaning

Before installation, clean the pipes to remove any dirt, oil, or debris that could affect the adhesion of the paint.

Use Appropriate Tools

Utilize tools specifically designed for cutting and joining galvanized pipes to prevent damage to the protective coating.

Secure Joining Methods

Employ secure joining methods, such as welding or using threaded fittings, to ensure a tight and leak-proof connection.

Follow Manufacturer Instructions

Always refer to the manufacturer’s guidelines for installation procedures and recommendations specific to the product.

Maintenance Best Practices

To ensure the longevity of painted galvanized steel pipes, implement the following maintenance practices:

Regular Inspections

Conduct routine inspections to identify any signs of wear or damage. Promptly address any issues to prevent further deterioration.

Cleaning

Keep the pipes clean by removing any dirt or debris that can trap moisture and lead to corrosion.

Touch-Up Painting

If the painted surface gets scratched or chipped, promptly apply touch-up paint to prevent rust formation.

Monitoring for Leaks

Regularly check for leaks, especially in plumbing applications, to ensure the integrity of the system.

Cost Considerations

Understanding the costs associated with painted galvanized steel pipes is essential for budgeting your construction project:

Initial Investment

The upfront costs for painted galvanized steel pipes may be higher than alternative materials, but consider the long-term returns due to their durability.

Installation Costs

Factor in the costs of labor for installation, as specialized techniques may require skilled labor to ensure proper handling and installation.

Maintenance Costs

Evaluate the expected maintenance costs over the life of the piping. The reduced frequency of repairs can lead to significant savings.

Frequently Asked Questions

1. What is the difference between galvanized and painted galvanized steel pipes?

Galvanized pipes are coated with zinc for corrosion resistance, while painted galvanized pipes have an additional layer of paint for enhanced aesthetics and protection.

2. How long do painted galvanized steel pipes last?

With proper installation and maintenance, painted galvanized steel pipes can last for several decades, often exceeding 50 years.

3. Can painted galvanized steel pipes be used for drinking water systems?

Yes, as long as they comply with local regulations regarding potable water systems, painted galvanized pipes can be used for drinking water.

4. Are painted galvanized pipes environmentally friendly?

Yes, galvanized steel pipes are recyclable, and their durability reduces the need for frequent replacements, contributing to environmental sustainability.

5. How do I properly maintain painted galvanized steel pipes?

Regular inspections, cleaning, and addressing any damage to the paint are essential practices for maintaining the longevity of these pipes.

Conclusion

Choosing the **best painted galvanized steel pipes** for your construction project is a vital decision that impacts both the longevity and functionality of the structure. Understanding the advantages, applications, and maintenance practices associated with these pipes allows you to make informed choices that ensure your project's success. By selecting high-quality materials and adhering to best practices in installation and maintenance, you can confidently enhance the durability and aesthetic appeal of your construction endeavors. Make the right choice today for a stronger, more resilient tomorrow.

TAG:

Related Posts

Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

Exploring the Benefits of Coated Steel Pipes for Natural Gas Applications in China

Table of Contents

1. Introduction to Coated Steel Pipes

2. The Importance of Coated Steel Pipes in Natural Gas Applications

3. Key Advantages of Coated Steel Pipes

3.1 Enhanced Corrosion Resistance

3.2 Increased Longevity and Durability

3.3 Improved Safety Standards

4. Types of Coatings Used in Steel