Exploring the Advantages of the Latest API 5L 3PE Coated Pipes for Construction Projects

May 27,2025

Exploring the Advantages of the Latest API 5L 3PE Coated Pipes for Construction Projects

Table of Contents

1. Introduction to API 5L 3PE Coated Pipes

2. Understanding the API 5L Standard

3. What Are 3PE Coated Pipes?

4. Benefits of 3PE Coating for Construction

4.1 Durability and Longevity

4.2 Corrosion Resistance

4.3 Cost-Effectiveness

4.4 Environmental Benefi

Exploring the Advantages of the Latest API 5L 3PE Coated Pipes for Construction Projects

Table of Contents

- 1. Introduction to API 5L 3PE Coated Pipes

- 2. Understanding the API 5L Standard

- 3. What Are 3PE Coated Pipes?

- 4. Benefits of 3PE Coating for Construction

- 4.1 Durability and Longevity

- 4.2 Corrosion Resistance

- 4.3 Cost-Effectiveness

- 4.4 Environmental Benefits

- 4.5 Ease of Installation

- 5. Practical Applications of API 5L 3PE Coated Pipes

- 6. Notable Case Studies

- 7. Future Trends in Coated Pipeline Technology

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to API 5L 3PE Coated Pipes

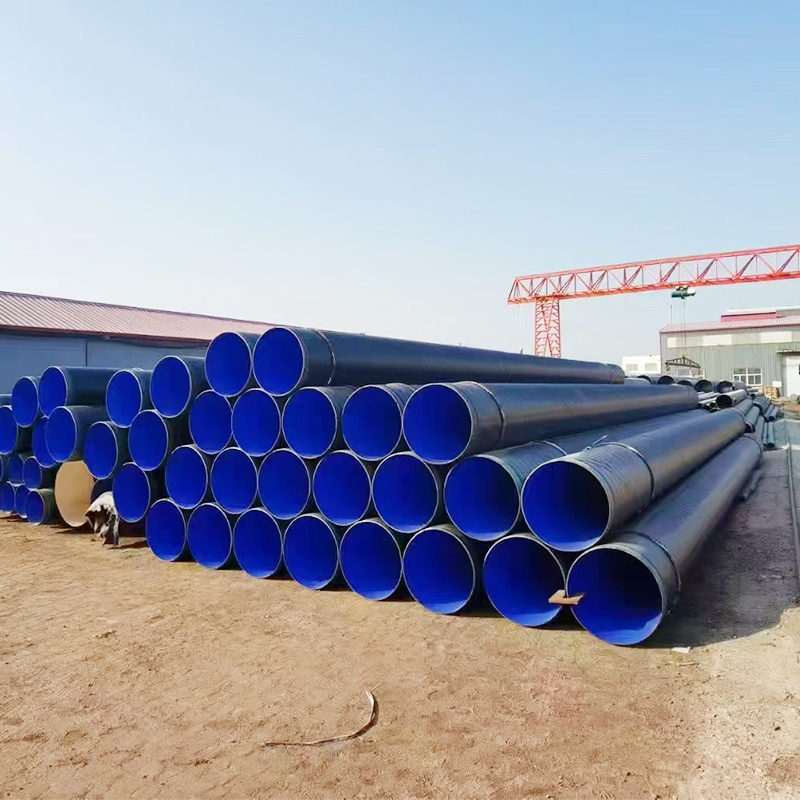

API 5L 3PE coated pipes are revolutionizing the construction industry with their advanced protective features and performance capabilities. These pipes are designed to meet the stringent requirements of various construction applications, making them essential for long-lasting infrastructure projects. The fusion of the API 5L standard with the innovative 3PE coating creates a robust solution that addresses the challenges faced in construction.

2. Understanding the API 5L Standard

API 5L is an American Petroleum Institute specification that governs the manufacturing of line pipes used in the transportation of oil, gas, and water. It sets forth the requirements for pipe designs, materials, and testing methods to ensure quality and reliability. The API 5L standard categorizes the pipes into different grades based on their yield strength and chemical composition, ensuring that they meet the necessary performance benchmarks for various applications.

3. What Are 3PE Coated Pipes?

3PE, or three-layer polyethylene, is a protective coating system used on steel pipes to enhance their durability and resistance to external factors. This coating consists of three layers: a fusion-bonded epoxy primer, a middle adhesive layer, and an outer layer of polyethylene. Each layer serves a specific purpose—protecting against corrosion, providing adhesion, and shielding from mechanical damage, respectively. This comprehensive coating system makes 3PE coated pipes ideal for construction projects exposed to harsh environments.

4. Benefits of 3PE Coating for Construction

The adoption of API 5L 3PE coated pipes offers numerous advantages that can significantly improve the efficiency and longevity of construction projects.

4.1 Durability and Longevity

One of the primary benefits of 3PE coated pipes is their exceptional durability. The three-layer system provides a formidable barrier against physical damage and environmental conditions, extending the life span of the pipes. This durability means fewer replacements and repairs over time, making it a wise investment for construction companies.

4.2 Corrosion Resistance

Corrosion is one of the leading causes of pipeline failure. The 3PE coating effectively prevents moisture and corrosive agents from reaching the steel surface, significantly reducing the risk of corrosion. This resistance is particularly beneficial in projects located in humid, coastal, or chemically aggressive environments.

4.3 Cost-Effectiveness

While the initial cost of API 5L 3PE coated pipes may be higher than uncoated alternatives, the long-term savings are considerable. The reduced maintenance costs, prolonged service life, and lower risk of failure contribute to significant cost savings over the lifespan of a project. Furthermore, fewer interruptions in service due to repairs lead to enhanced operational efficiency.

4.4 Environmental Benefits

Using API 5L 3PE coated pipes is not only economically advantageous but also environmentally responsible. The longevity and reduced maintenance requirements minimize waste generation and resource consumption. Furthermore, the materials used in the 3PE coating are often recyclable, contributing to a more sustainable construction practice.

4.5 Ease of Installation

API 5L 3PE coated pipes are designed for ease of installation. The lightweight nature of the coated pipes, combined with their robust design, simplifies handling and reduces labor costs during installation. This efficiency allows construction projects to proceed on schedule without the delays often encountered with heavier, more cumbersome materials.

5. Practical Applications of API 5L 3PE Coated Pipes

API 5L 3PE coated pipes are versatile and can be used in various applications, including:

- Oil and Gas Transportation: Their resistance to corrosion and mechanical stress makes them ideal for transporting oil and natural gas.

- Water Distribution: The durability of these pipes ensures reliable performance in municipal water systems.

- Industrial Applications: Factories and plants often require robust piping solutions that can withstand harsh chemicals and high pressures.

- Infrastructure Projects: Roads, bridges, and tunnels benefit from the longevity and durability of API 5L 3PE coated pipes, ensuring long-term structural integrity.

6. Notable Case Studies

Examining real-world applications of API 5L 3PE coated pipes highlights their effectiveness in various projects. For instance, a major water supply project in an industrial area employed these pipes to withstand aggressive environmental conditions. The project successfully minimized maintenance downtime, showcasing the reliability of these coated pipes.

7. Future Trends in Coated Pipeline Technology

As technology advances, the pipeline industry is expected to see further innovations in coating materials and techniques. Future trends may include the development of coatings with enhanced protective features, eco-friendly materials, and smart technology integration to monitor pipeline conditions in real time. Staying abreast of these trends will be essential for construction companies aiming to maintain their competitive edge.

8. Conclusion

The API 5L 3PE coated pipes are setting new standards in the construction industry by offering unmatched durability, corrosion resistance, and cost-effectiveness. With their versatile applications, these pipes are essential for any construction project that prioritizes longevity and reliability. Investing in API 5L 3PE coated pipes not only ensures a robust solution for today’s challenges but also showcases a commitment to sustainability and efficient resource management.

9. Frequently Asked Questions

1. What does API 5L stand for?

API 5L stands for the American Petroleum Institute's specification for line pipe used in the transportation of oil, gas, and water.

2. What are the advantages of using 3PE coated pipes?

The advantages of using 3PE coated pipes include enhanced durability, corrosion resistance, cost-effectiveness, ease of installation, and environmental benefits.

3. Can API 5L 3PE coated pipes be used in all environments?

Yes, API 5L 3PE coated pipes are designed to perform well in various environments, including those with high humidity and aggressive chemicals.

4. How does the cost of API 5L 3PE coated pipes compare to uncoated pipes?

While API 5L 3PE coated pipes may have a higher initial cost, their long-term benefits, including reduced maintenance and prolonged life span, make them more cost-effective over time.

5. Are 3PE coated pipes environmentally friendly?

Yes, the longevity and recyclability of 3PE coated pipes contribute to environmentally friendly construction practices by minimizing waste and resource consumption.

TAG:

Related Posts

Transform Your Spaces with Striking Red Painted Steel Pipe Spots: A Comprehensive Guide

Transform Your Spaces with Striking Red Painted Steel Pipe Spots

Table of Contents

1. Introduction: The Rise of Industrial Aesthetics

2. Understanding Steel Pipes: Types and Uses in Construction

3. Why Choose Red Painted Steel Pipes for Your Decor?

4. Creative Applications of Red Painted Steel Pipe Spots

5. Design Inspiration: Transforming Spaces with Steel

6. Installation