3PE Epoxy Coated Steel Pipe Innovations in Today’s Market: A Comprehensive Analysis

May 29,2025

3PE Epoxy Coated Steel Pipe Innovations in Today’s Market

Table of Contents

Introduction to 3PE Epoxy Coated Steel Pipes

What is 3PE Epoxy Coating?

Advantages of 3PE Coating in Steel Pipes

Recent Innovations in 3PE Coated Steel Pipes

Applications of 3PE Epoxy Coated Steel Pipes

Environmental Impact and Sustainability

Future Trends in 3PE Coating Technology

Conclusion

Frequently

3PE Epoxy Coated Steel Pipe Innovations in Today’s Market

Table of Contents

- Introduction to 3PE Epoxy Coated Steel Pipes

- What is 3PE Epoxy Coating?

- Advantages of 3PE Coating in Steel Pipes

- Recent Innovations in 3PE Coated Steel Pipes

- Applications of 3PE Epoxy Coated Steel Pipes

- Environmental Impact and Sustainability

- Future Trends in 3PE Coating Technology

- Conclusion

- Frequently Asked Questions

Introduction to 3PE Epoxy Coated Steel Pipes

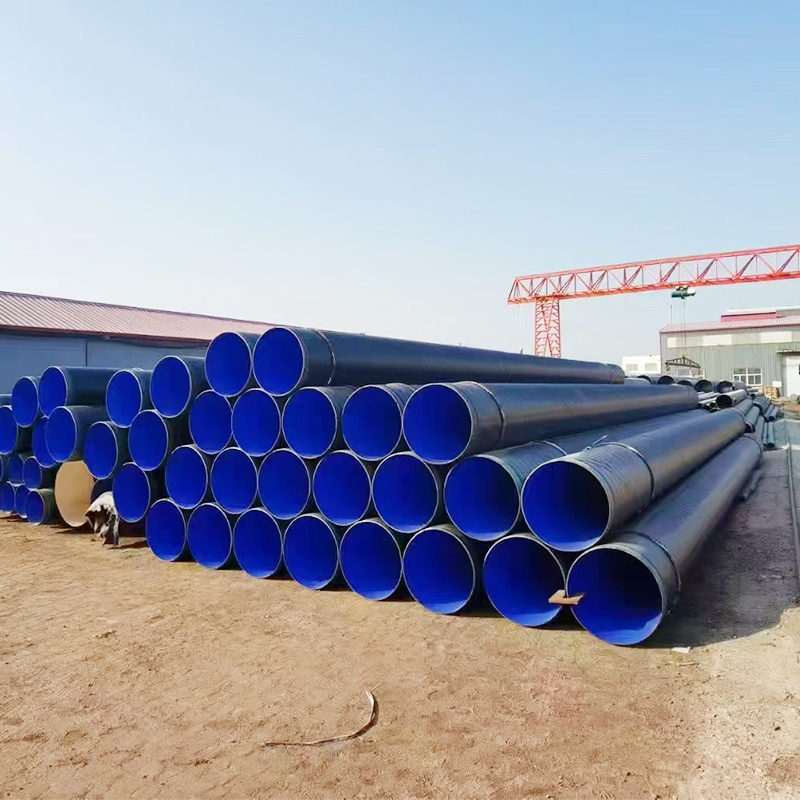

3PE epoxy coated steel pipes represent a significant advancement in the construction and decoration materials industry. The combination of steel's strength with innovative epoxy coatings results in a product that offers both durability and longevity. As we explore this topic, we will uncover how 3PE epoxy coating is revolutionizing the way we approach infrastructure and construction projects.

What is 3PE Epoxy Coating?

3PE, or three-layer polyethylene, is a sophisticated protective coating system used primarily on steel pipes. This system consists of three distinct layers:

1. Epoxy Primer Layer

The first layer is an epoxy primer that provides excellent adhesion to the steel surface while protecting against corrosion. This layer serves as a barrier to moisture and harmful substances.

2. Adhesive Layer

Next, an adhesive layer binds the epoxy layer to the outer polyethylene layer. This layer is crucial for ensuring the longevity of the coating system.

3. Polyethylene Outer Layer

Finally, the outer layer of polyethylene acts as a shield against environmental factors, mechanical damage, and UV radiation. This combination of layers creates a robust protective barrier that enhances the pipe's overall durability.

Advantages of 3PE Coating in Steel Pipes

The advantages of using 3PE epoxy coated steel pipes are numerous, making them a preferred choice in various applications.

Corrosion Resistance

One of the most significant benefits of 3PE coating is its exceptional resistance to corrosion. This property ensures that steel pipes maintain their structural integrity over time, even in harsh environments.

Extended Lifespan

The combination of the protective layers not only prolongs the life of the steel pipe but also reduces maintenance costs associated with corrosion damage.

Cost-Effectiveness

While the initial investment in 3PE coated steel pipes may be higher than traditional options, the long-term savings from reduced maintenance and replacement costs make them a cost-effective solution.

Recent Innovations in 3PE Coated Steel Pipes

The market has witnessed several innovations in 3PE epoxy coated steel pipes that enhance performance and application.

Advanced Coating Techniques

Recent advancements in coating technology have led to more uniform application processes, ensuring that the protective layers are applied consistently, which reduces the risk of weak spots.

Improved Adhesion Properties

Innovations in adhesive technology have improved the bonding strength between the epoxy and polyethylene layers, further enhancing the overall durability of the pipes.

Customization Options

Manufacturers are now offering customizable solutions, allowing clients to tailor the coating characteristics based on specific environmental and application needs.

Applications of 3PE Epoxy Coated Steel Pipes

3PE epoxy coated steel pipes find extensive use across various sectors. Their versatility makes them suitable for projects ranging from water supply systems to oil and gas pipelines.

Water Supply and Drainage Systems

In municipal water systems, the corrosion resistance of 3PE coatings ensures clean, potable water delivery while minimizing maintenance costs.

Oil and Gas Industry

In the oil and gas sector, these pipes are essential for transporting volatile substances across vast distances, offering safety and reliability.

Infrastructure Projects

3PE coated steel pipes are increasingly used in infrastructure projects where durability and long lifespan are critical factors.

Environmental Impact and Sustainability

The use of 3PE epoxy coated steel pipes also aligns with sustainability goals in the construction industry.

Reduced Resource Consumption

By extending the lifespan of pipes, 3PE technology reduces the need for frequent replacements, thereby conserving materials and energy.

Recyclability

Both steel and polyethylene are recyclable materials, making 3PE coated pipes an environmentally friendly choice when the end of their lifecycle is reached.

Future Trends in 3PE Coating Technology

Looking ahead, the future of 3PE epoxy coated steel pipes appears promising.

Smart Coatings

The integration of smart technology into coatings, allowing for real-time monitoring of structural integrity and environmental conditions, is gaining traction.

Enhanced Performance Materials

Research into new materials that enhance the protective qualities of coatings is ongoing, leading to even more resilient solutions for various applications.

Conclusion

In conclusion, 3PE epoxy coated steel pipes are at the forefront of innovation in the construction and decoration materials industry. Their unique combination of strength, durability, and resistance to corrosion makes them a preferred choice for various applications. With ongoing advancements in coating technology and a focus on sustainability, these pipes are set to play an increasingly vital role in modern infrastructure projects.

Frequently Asked Questions

1. What is the main purpose of 3PE epoxy coating?

The primary purpose of 3PE epoxy coating is to provide corrosion resistance and enhance the durability of steel pipes, ensuring they maintain their structural integrity over time.

2. How long do 3PE coated steel pipes last?

With proper installation and maintenance, 3PE coated steel pipes can last several decades, significantly reducing the need for replacements.

3. Are 3PE coated pipes environmentally friendly?

Yes, 3PE coated pipes are considered environmentally friendly due to their recyclability and the extended lifespan that reduces resource consumption.

4. What industries commonly use 3PE epoxy coated steel pipes?

3PE epoxy coated steel pipes are primarily used in the water supply, oil and gas industries, and various infrastructure projects.

5. Can 3PE epoxy coated pipes be customized for specific applications?

Absolutely! Manufacturers now offer customizable 3PE coating solutions tailored to meet specific environmental conditions and application requirements.

TAG:

Related Posts

Transform Your Spaces with Striking Red Painted Steel Pipe Spots: A Comprehensive Guide

Transform Your Spaces with Striking Red Painted Steel Pipe Spots

Table of Contents

1. Introduction: The Rise of Industrial Aesthetics

2. Understanding Steel Pipes: Types and Uses in Construction

3. Why Choose Red Painted Steel Pipes for Your Decor?

4. Creative Applications of Red Painted Steel Pipe Spots

5. Design Inspiration: Transforming Spaces with Steel

6. Installation