Why Choose Underground Insulated Steel Pipe for Your Next Project?

Jun 14,2025

Why Choose Underground Insulated Steel Pipe for Your Next Project?

Underground insulated steel pipes have emerged as a preferred option in the construction and building materials industry, particularly for projects requiring long-lasting, energy-efficient solutions. Understanding the benefits and applications of these pipes can significantly impact the success of your project. In this article, we

Why Choose Underground Insulated Steel Pipe for Your Next Project?

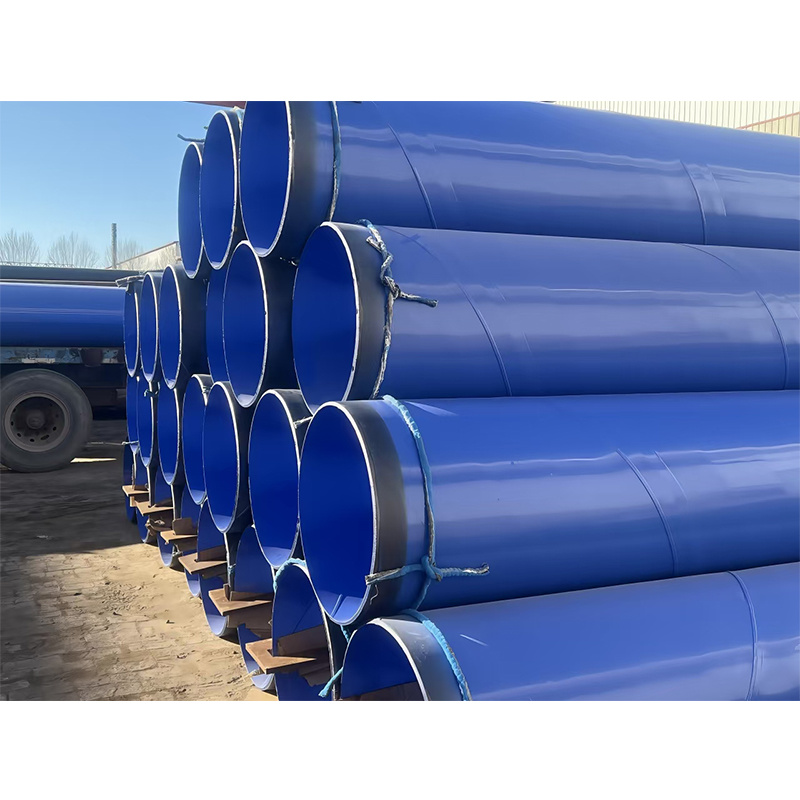

Underground insulated steel pipes have emerged as a preferred option in the construction and building materials industry, particularly for projects requiring long-lasting, energy-efficient solutions. Understanding the benefits and applications of these pipes can significantly impact the success of your project. In this article, we delve into the numerous reasons to choose underground insulated steel pipes for your next venture, covering everything from thermal efficiency to installation advantages.

Table of Contents

- 1. Benefits of Underground Insulated Steel Pipe

- 2. Thermal Efficiency and Energy Savings

- 3. Durability and Longevity of Steel Pipes

- 4. Cost-Effectiveness of Underground Insulated Steel Pipe

- 5. Environmental Considerations

- 6. Installation Process and Best Practices

- 7. Applications of Underground Insulated Steel Pipe

- 8. Frequently Asked Questions

- 9. Conclusion

1. Benefits of Underground Insulated Steel Pipe

Underground insulated steel pipes possess a unique combination of features that make them stand out in the construction industry. These pipes are engineered to withstand harsh environmental conditions, ensuring reliability and efficiency in various applications. Key benefits include:

- **Enhanced thermal insulation**: The insulation layer provides superior protection against heat loss, making these pipes ideal for transporting hot fluids.

- **Corrosion resistance**: Steel, when properly coated, offers excellent resistance to corrosion, ensuring a longer lifespan in underground settings.

- **Structural integrity**: Steel pipes maintain their structural integrity over time, even under high-pressure conditions.

By choosing underground insulated steel pipes, you invest in a solution that promises performance and longevity, reducing the need for frequent replacements.

2. Thermal Efficiency and Energy Savings

One of the primary concerns in any construction project is energy efficiency. Underground insulated steel pipes excel in this area due to their exceptional thermal insulation properties. Here's why:

- **Reduced heat loss**: The insulation surrounding the steel pipe minimizes thermal conductivity, which means heat is retained during fluid transport, significantly reducing energy consumption.

- **Lower operational costs**: By minimizing heat loss, these pipes help lower the energy bills associated with heating systems, leading to substantial cost savings over time.

- **Sustainable practices**: Choosing insulated pipes aligns with sustainable construction practices, as they contribute to reduced carbon footprints and lower energy usage.

Incorporating underground insulated steel pipes into your projects can lead to considerable energy savings, enhancing the overall sustainability of your construction methods.

3. Durability and Longevity of Steel Pipes

When selecting materials for underground applications, durability is paramount. Underground insulated steel pipes offer several advantages in this regard:

- **Resistance to external pressures**: These pipes are designed to withstand extreme pressure, making them suitable for deep burial and heavy loads.

- **Longevity**: With proper maintenance and insulation, steel pipes can last for decades without significant degradation, ensuring that your investment pays off in the long run.

- **Minimal maintenance**: Steel’s durability means reduced maintenance requirements, freeing up resources for other project aspects.

By choosing underground insulated steel pipes, you ensure longevity and reliability, which translates to fewer disruptions and lower maintenance costs in the lifespan of your infrastructure.

4. Cost-Effectiveness of Underground Insulated Steel Pipe

Cost considerations are often a driving factor in material selection for construction projects. Underground insulated steel pipes offer a cost-effective solution for several reasons:

- **Initial investment vs. long-term savings**: While the upfront costs may be higher than traditional piping options, the long-term energy savings and reduced maintenance expenses justify the investment.

- **Reduced installation costs**: The installation process for insulated pipes can be more straightforward due to their flexibility and lightweight properties, potentially lowering labor costs.

- **Longevity reduces replacement needs**: The durability of these pipes means fewer replacements are necessary over time, which results in cost savings for project owners.

Opting for underground insulated steel pipes is not only a smart choice for energy efficiency but also a savvy financial decision that can lead to substantial savings for your project.

5. Environmental Considerations

In today's environmentally conscious world, selecting sustainable materials is crucial for any construction project. Underground insulated steel pipes align well with these sustainability goals:

- **Energy efficiency**: As previously mentioned, these pipes help reduce energy consumption, which directly correlates with lower greenhouse gas emissions.

- **Recyclability**: Steel is one of the most recycled materials globally, making it an environmentally friendly option. At the end of their life cycle, these pipes can be recycled rather than sent to landfills.

- **Low environmental impact**: The production processes for insulated steel pipes have become increasingly eco-friendly, minimizing their carbon footprint compared to other materials.

By integrating underground insulated steel pipes into your project, you are not only improving efficiency but also contributing to a more sustainable future.

6. Installation Process and Best Practices

The installation of underground insulated steel pipes requires careful planning and execution. Here are some best practices to ensure a successful installation:

- **Site preparation**: Conduct thorough site assessments to determine the best locations for installation, considering factors like soil type and moisture levels.

- **Proper handling**: Ensure pipes are handled with care to avoid damage to the insulation and steel. Use appropriate equipment and techniques during transportation and installation.

- **Sealing joints**: Ensure that all joints are properly sealed to prevent leaks and maintain thermal efficiency. Using high-quality adhesives and techniques is crucial for long-term performance.

- **Regular inspections**: Post-installation, conduct regular inspections to catch any issues early, ensuring ongoing performance and longevity.

Following these best practices can significantly enhance the performance and lifespan of your underground insulated steel pipe installations.

7. Applications of Underground Insulated Steel Pipe

Underground insulated steel pipes are versatile and can be utilized across various sectors. Here are some common applications:

- **District heating systems**: These pipes are ideal for transporting hot water over long distances, providing efficient heating to residential and commercial buildings.

- **Industrial applications**: Many industries rely on these pipes for transporting steam and heated fluids in processes requiring precise temperature control.

- **Wastewater management**: Insulated pipes can also be used for transporting wastewater at controlled temperatures, preventing solidification and ensuring efficient processing.

- **Geothermal systems**: The thermal efficiency of these pipes makes them suitable for geothermal heating systems, where maintaining temperature is crucial.

The adaptability of underground insulated steel pipes makes them a go-to solution for various industries and applications, enhancing their value significantly.

8. Frequently Asked Questions

What is an underground insulated steel pipe?

Underground insulated steel pipes are piping systems designed to transport fluids underground while minimizing heat loss, featuring an insulation layer that enhances thermal efficiency.

How do insulated steel pipes improve energy efficiency?

Insulated steel pipes reduce heat loss during fluid transport, leading to lower energy consumption and operational costs.

Are insulated steel pipes environmentally friendly?

Yes, they contribute to sustainability by reducing energy consumption and are recyclable at the end of their life cycle.

What are the key benefits of using insulated steel pipes over traditional piping materials?

Key benefits include enhanced thermal efficiency, durability, reduced maintenance, and long-term cost savings.

What industries commonly use underground insulated steel pipes?

These pipes are widely used in district heating systems, industrial applications, wastewater management, and geothermal systems.

9. Conclusion

Choosing underground insulated steel pipes for your next construction project presents a multitude of benefits, from enhanced thermal efficiency and durability to long-term cost-effectiveness and environmental sustainability. These pipes not only provide reliable solutions for transporting fluids but also contribute to reducing energy consumption and promoting eco-friendly practices. By understanding the advantages and applications of underground insulated steel pipes, you can make an informed decision that ensures the success and sustainability of your projects. With their proven performance and versatility, underground insulated steel pipes stand out as an excellent choice for modern construction needs.

TAG:

Related Posts

Why Choose Underground Insulated Steel Pipe for Your Next Project?

Why Choose Underground Insulated Steel Pipe for Your Next Project?

Underground insulated steel pipes have emerged as a preferred option in the construction and building materials industry, particularly for projects requiring long-lasting, energy-efficient solutions. Understanding the benefits and applications of these pipes can significantly impact the success of your project. In this article, we