Understanding Quality 3-Layer Polyethylene Steel Pipe: A Comprehensive Guide for Construction Professionals

Jun 21,2025

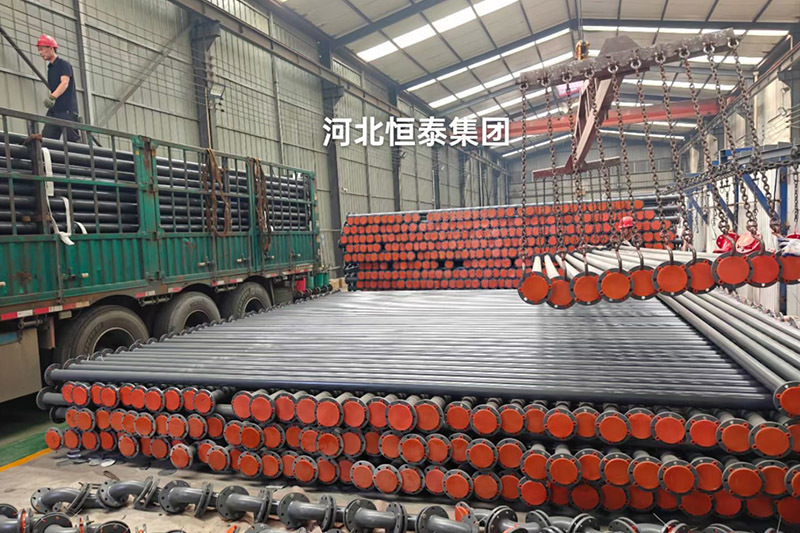

Quality 3-layer polyethylene steel pipes are increasingly recognized for their robustness and versatility in various applications within the construction and decoration sectors. These pipes consist of a composite structure that integrates a steel core with an outer layer of high-density polyethylene (HDPE). This unique design offers a range of benefits that enhance both performance and longevity.

Quality 3-layer polyethylene steel pipes are increasingly recognized for their robustness and versatility in various applications within the construction and decoration sectors. These pipes consist of a composite structure that integrates a steel core with an outer layer of high-density polyethylene (HDPE). This unique design offers a range of benefits that enhance both performance and longevity.

One of the key advantages of these pipes is their excellent resistance to corrosion. The outer polyethylene layer protects the steel core from environmental factors such as moisture, chemicals, and varying temperatures. This means that quality 3-layer polyethylene steel pipes can maintain their structural integrity and functionality even in harsh conditions, making them ideal for underground installations and industrial applications.

In addition to corrosion resistance, these pipes also exhibit superior impact strength. The combination of steel and polyethylene allows them to withstand significant pressures and impacts without compromising their integrity. This characteristic is particularly beneficial in construction scenarios where pipes may be subject to heavy loads or accidental impacts.

Moreover, the lightweight nature of quality 3-layer polyethylene steel pipes simplifies handling and installation processes. This can lead to reduced labor costs and quicker project timelines, which are critical factors in the competitive construction industry. Professionals can easily transport and manipulate these pipes, making them a practical choice for both large-scale projects and smaller renovation works.

Another aspect to consider is the thermal insulation properties of these pipes. The polyethylene layer provides effective insulation, which can help minimize heat loss or gain, depending on the application. This feature is particularly beneficial in plumbing systems where maintaining water temperature is essential.

When selecting quality 3-layer polyethylene steel pipes for your projects, it is important to consider the specifications that match your specific needs. Factors such as diameter, pressure rating, and compliance with local building codes should be thoroughly evaluated. Working with reputable suppliers who provide detailed technical information and testing results can ensure that you make informed decisions.

In summary, quality 3-layer polyethylene steel pipes offer a combination of corrosion resistance, impact strength, lightweight handling, and thermal insulation, making them a preferred choice in the construction and decoration materials industry. By understanding the benefits and specifications of these pipes, professionals can enhance their projects' performance and reliability while remaining competitive in the market.

One of the key advantages of these pipes is their excellent resistance to corrosion. The outer polyethylene layer protects the steel core from environmental factors such as moisture, chemicals, and varying temperatures. This means that quality 3-layer polyethylene steel pipes can maintain their structural integrity and functionality even in harsh conditions, making them ideal for underground installations and industrial applications.

In addition to corrosion resistance, these pipes also exhibit superior impact strength. The combination of steel and polyethylene allows them to withstand significant pressures and impacts without compromising their integrity. This characteristic is particularly beneficial in construction scenarios where pipes may be subject to heavy loads or accidental impacts.

Moreover, the lightweight nature of quality 3-layer polyethylene steel pipes simplifies handling and installation processes. This can lead to reduced labor costs and quicker project timelines, which are critical factors in the competitive construction industry. Professionals can easily transport and manipulate these pipes, making them a practical choice for both large-scale projects and smaller renovation works.

Another aspect to consider is the thermal insulation properties of these pipes. The polyethylene layer provides effective insulation, which can help minimize heat loss or gain, depending on the application. This feature is particularly beneficial in plumbing systems where maintaining water temperature is essential.

When selecting quality 3-layer polyethylene steel pipes for your projects, it is important to consider the specifications that match your specific needs. Factors such as diameter, pressure rating, and compliance with local building codes should be thoroughly evaluated. Working with reputable suppliers who provide detailed technical information and testing results can ensure that you make informed decisions.

In summary, quality 3-layer polyethylene steel pipes offer a combination of corrosion resistance, impact strength, lightweight handling, and thermal insulation, making them a preferred choice in the construction and decoration materials industry. By understanding the benefits and specifications of these pipes, professionals can enhance their projects' performance and reliability while remaining competitive in the market.

TAG:

Related Posts

How Customized API 5L 3PE Coated Pipes Enhance Construction Durability

How Customized API 5L 3PE Coated Pipes Enhance Construction Durability

Table of Contents

Introduction to API 5L 3PE Coated Pipes

What Are API 5L 3PE Coated Pipes?

Benefits of Customization in API 5L 3PE Coated Pipes

How 3PE Coating Works to Enhance Durability

Applications of API 5L 3PE Coated Pipes in Construction

Sustainability and Environmental Impact of API 5L 3PE Coate