Understanding 3PE Seamless Steel Pipes: A Comprehensive Guide

Jun 25,2025

3PE seamless steel pipes are gaining popularity in the construction and decoration materials industry due to their outstanding properties and versatility. The term "3PE" refers to a three-layer polyethylene coating that is applied to the steel pipe to enhance its corrosion resistance. This coating system combines the protective benefits of epoxy primer, adhesive, and polyethylene, making it an exc

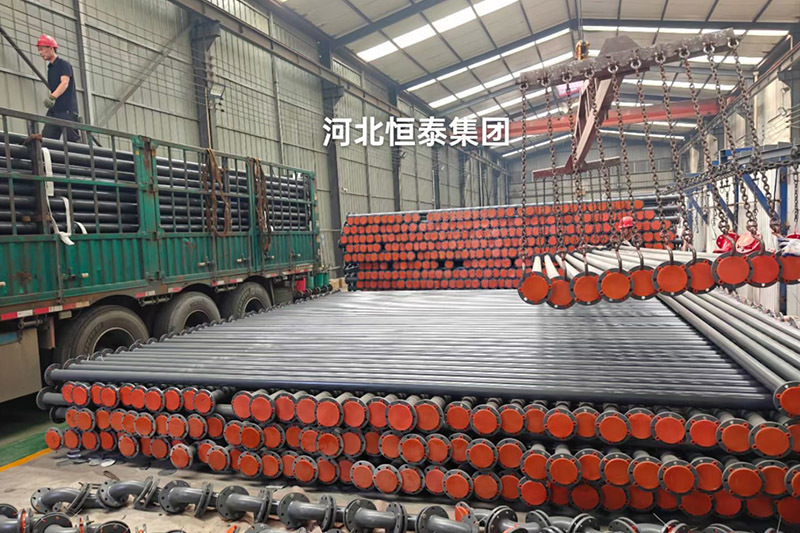

3PE seamless steel pipes are gaining popularity in the construction and decoration materials industry due to their outstanding properties and versatility. The term "3PE" refers to a three-layer polyethylene coating that is applied to the steel pipe to enhance its corrosion resistance. This coating system combines the protective benefits of epoxy primer, adhesive, and polyethylene, making it an excellent choice for various applications, particularly in environments where moisture and chemicals are concerns.

One of the primary advantages of 3PE seamless steel pipes is their durability. The seamless manufacturing process eliminates welds and joints, resulting in a pipe that can withstand higher pressures and is less prone to leakage. This characteristic makes them ideal for transporting fluids, gases, and other materials in construction projects. Their structural integrity is crucial, especially in high-stress applications such as pipelines, structural components, and water transmission systems.

Additionally, the 3PE coating significantly extends the lifespan of the pipes, reducing the need for frequent replacements. This longevity is particularly beneficial in infrastructure projects where maintenance costs can be a significant concern. Furthermore, the smooth inner surface of seamless steel pipes minimizes friction, allowing for more efficient flow rates and energy savings.

From an environmental perspective, 3PE seamless steel pipes are also a responsible choice. Their long service life and resistance to corrosion mean they contribute to reduced waste and lower environmental impact over time. When these pipes do reach the end of their lifecycle, they can often be recycled, aligning with sustainable construction practices.

In terms of applications, 3PE seamless steel pipes are widely used in various sectors including oil and gas, water supply, and construction. They are suitable for both above-ground and underground installations, making them incredibly versatile. Their ability to resist harsh environmental conditions further enhances their suitability for projects in diverse locations.

In summary, 3PE seamless steel pipes represent a robust and reliable choice for building materials within the construction industry. Their unique manufacturing process and protective coating ensure they meet the rigorous demands of modern construction projects. As more builders and contractors recognize the advantages of using these pipes, their popularity is likely to continue growing, reinforcing their position as a preferred material in construction and infrastructure development. Understanding the benefits and applications of 3PE seamless steel pipes can help industry professionals make informed decisions that enhance project efficiency and sustainability.

One of the primary advantages of 3PE seamless steel pipes is their durability. The seamless manufacturing process eliminates welds and joints, resulting in a pipe that can withstand higher pressures and is less prone to leakage. This characteristic makes them ideal for transporting fluids, gases, and other materials in construction projects. Their structural integrity is crucial, especially in high-stress applications such as pipelines, structural components, and water transmission systems.

Additionally, the 3PE coating significantly extends the lifespan of the pipes, reducing the need for frequent replacements. This longevity is particularly beneficial in infrastructure projects where maintenance costs can be a significant concern. Furthermore, the smooth inner surface of seamless steel pipes minimizes friction, allowing for more efficient flow rates and energy savings.

From an environmental perspective, 3PE seamless steel pipes are also a responsible choice. Their long service life and resistance to corrosion mean they contribute to reduced waste and lower environmental impact over time. When these pipes do reach the end of their lifecycle, they can often be recycled, aligning with sustainable construction practices.

In terms of applications, 3PE seamless steel pipes are widely used in various sectors including oil and gas, water supply, and construction. They are suitable for both above-ground and underground installations, making them incredibly versatile. Their ability to resist harsh environmental conditions further enhances their suitability for projects in diverse locations.

In summary, 3PE seamless steel pipes represent a robust and reliable choice for building materials within the construction industry. Their unique manufacturing process and protective coating ensure they meet the rigorous demands of modern construction projects. As more builders and contractors recognize the advantages of using these pipes, their popularity is likely to continue growing, reinforcing their position as a preferred material in construction and infrastructure development. Understanding the benefits and applications of 3PE seamless steel pipes can help industry professionals make informed decisions that enhance project efficiency and sustainability.

TAG:

Related Posts

How Customized API 5L 3PE Coated Pipes Enhance Construction Durability

How Customized API 5L 3PE Coated Pipes Enhance Construction Durability

Table of Contents

Introduction to API 5L 3PE Coated Pipes

What Are API 5L 3PE Coated Pipes?

Benefits of Customization in API 5L 3PE Coated Pipes

How 3PE Coating Works to Enhance Durability

Applications of API 5L 3PE Coated Pipes in Construction

Sustainability and Environmental Impact of API 5L 3PE Coate