Understanding the Role of PE Coated Steel Pipe Exporters in the Construction Industry

Jul 05,2025

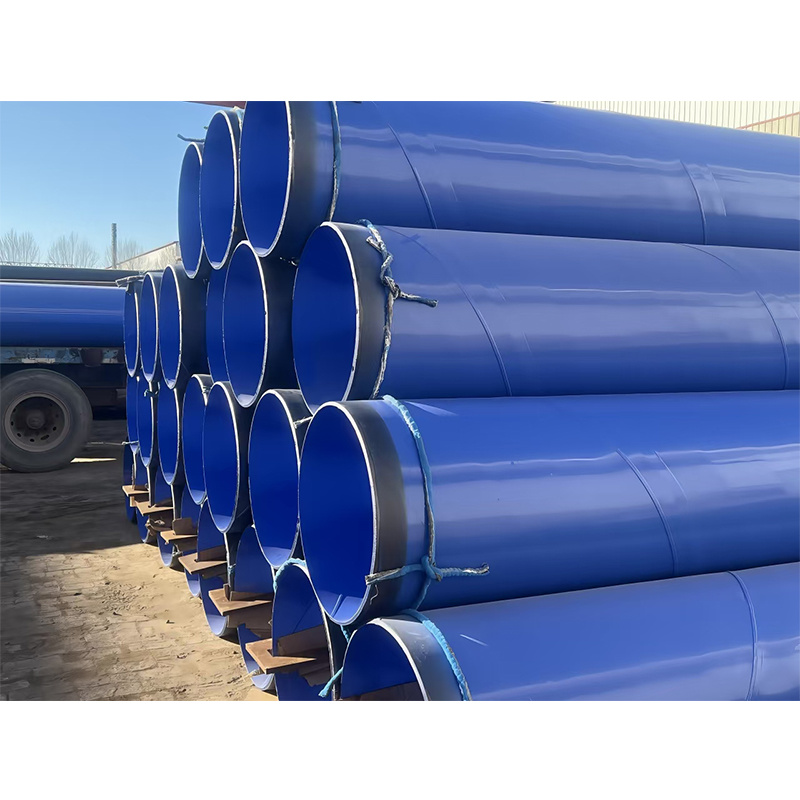

PE coated steel pipes have become increasingly popular in the construction and decoration materials industry due to their durability, corrosion resistance, and versatility. As construction projects demand materials that can withstand the test of time and environmental challenges, PE coated steel pipe exporters play a crucial role in supplying these essential products.

PE, or polyethylene, is a the

PE coated steel pipes have become increasingly popular in the construction and decoration materials industry due to their durability, corrosion resistance, and versatility. As construction projects demand materials that can withstand the test of time and environmental challenges, PE coated steel pipe exporters play a crucial role in supplying these essential products.

PE, or polyethylene, is a thermoplastic material that is resistant to chemicals and moisture. When applied as a coating on steel pipes, it enhances the pipes' performance significantly. Steel pipes by themselves, although strong, are susceptible to rust and corrosion when exposed to moisture, chemicals, or varying weather conditions. By using a PE coating, manufacturers can provide an additional layer of protection that extends the lifespan of the pipes, making them ideal for a range of applications.

PE coated steel pipes are widely used in various sectors, including water supply, gas distribution, and even in construction for structural purposes. Their applications are not limited to underground systems; they are also used in above-ground systems where exposure to the elements is a concern. This versatility is why PE coated steel pipe exporters are integral to the supply chain in the construction industry.

Another significant advantage of PE coated steel pipes is their ease of handling and installation. The lightweight nature of the pipes, combined with the protective coating, means they can be easily transported and installed without fear of damage. This is particularly beneficial on construction sites, where efficiency and effectiveness are paramount.

Quality is a critical factor when it comes to selecting PE coated steel pipe exporters. The integrity of the coating and the quality of the steel used can greatly affect the performance of the pipes in real-world applications. Therefore, it is vital for construction companies to collaborate with reputable exporters who adhere to industry standards and rigorous quality control measures. This ensures that the materials used in construction projects meet safety regulations and perform reliably over time.

Moreover, as sustainability becomes an increasingly important focus in construction, PE coated steel pipes offer an eco-friendly alternative. The longevity and durability of these pipes mean less waste and fewer replacements over time, aligning with green building practices.

In summary, PE coated steel pipe exporters serve a vital function in the construction industry by providing durable, corrosion-resistant materials that enhance the performance of various systems. Their role is essential not only in ensuring the quality of construction projects but also in promoting sustainable practices within the industry. Understanding the benefits and applications of these products can help stakeholders make informed decisions for their construction needs.

PE, or polyethylene, is a thermoplastic material that is resistant to chemicals and moisture. When applied as a coating on steel pipes, it enhances the pipes' performance significantly. Steel pipes by themselves, although strong, are susceptible to rust and corrosion when exposed to moisture, chemicals, or varying weather conditions. By using a PE coating, manufacturers can provide an additional layer of protection that extends the lifespan of the pipes, making them ideal for a range of applications.

PE coated steel pipes are widely used in various sectors, including water supply, gas distribution, and even in construction for structural purposes. Their applications are not limited to underground systems; they are also used in above-ground systems where exposure to the elements is a concern. This versatility is why PE coated steel pipe exporters are integral to the supply chain in the construction industry.

Another significant advantage of PE coated steel pipes is their ease of handling and installation. The lightweight nature of the pipes, combined with the protective coating, means they can be easily transported and installed without fear of damage. This is particularly beneficial on construction sites, where efficiency and effectiveness are paramount.

Quality is a critical factor when it comes to selecting PE coated steel pipe exporters. The integrity of the coating and the quality of the steel used can greatly affect the performance of the pipes in real-world applications. Therefore, it is vital for construction companies to collaborate with reputable exporters who adhere to industry standards and rigorous quality control measures. This ensures that the materials used in construction projects meet safety regulations and perform reliably over time.

Moreover, as sustainability becomes an increasingly important focus in construction, PE coated steel pipes offer an eco-friendly alternative. The longevity and durability of these pipes mean less waste and fewer replacements over time, aligning with green building practices.

In summary, PE coated steel pipe exporters serve a vital function in the construction industry by providing durable, corrosion-resistant materials that enhance the performance of various systems. Their role is essential not only in ensuring the quality of construction projects but also in promoting sustainable practices within the industry. Understanding the benefits and applications of these products can help stakeholders make informed decisions for their construction needs.

TAG:

Related Posts

Understanding the Role of PE Coated Steel Pipe Exporters in the Construction Industry

PE coated steel pipes have become increasingly popular in the construction and decoration materials industry due to their durability, corrosion resistance, and versatility. As construction projects demand materials that can withstand the test of time and environmental challenges, PE coated steel pipe exporters play a crucial role in supplying these essential products.

PE, or polyethylene, is a the