Choosing the Right Coated Steel Pipe Supplier for Your Construction Needs

Jul 10,2025

Choosing the Right Coated Steel Pipe Supplier for Your Construction Needs

Table of Contents

1. Understanding Coated Steel Pipes

2. The Importance of Coating in Steel Pipes

3. Key Factors to Consider When Choosing a Supplier

4. Assessing Supplier Reliability and Credentials

5. The Role of Quality Control and Certifications

6. Evaluating Supplier Communication and Support

Choosing the Right Coated Steel Pipe Supplier for Your Construction Needs

Table of Contents

- 1. Understanding Coated Steel Pipes

- 2. The Importance of Coating in Steel Pipes

- 3. Key Factors to Consider When Choosing a Supplier

- 4. Assessing Supplier Reliability and Credentials

- 5. The Role of Quality Control and Certifications

- 6. Evaluating Supplier Communication and Support

- 7. Cost-Effectiveness and Pricing Strategies

- 8. Frequently Asked Questions (FAQs)

- 9. Conclusion

1. Understanding Coated Steel Pipes

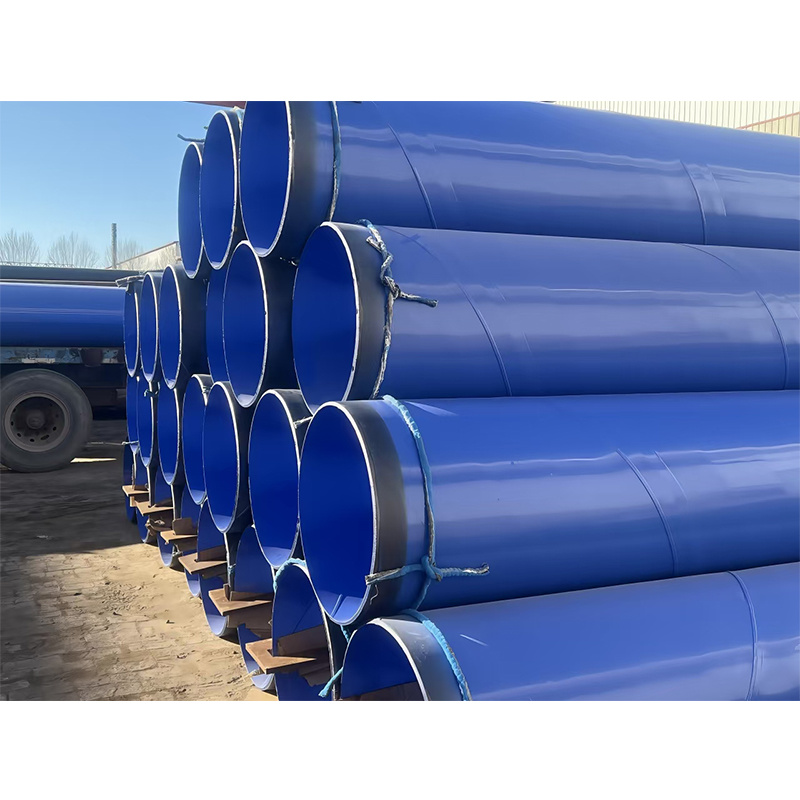

Coated steel pipes are integral components in various construction applications, known for their **enhanced durability** and **corrosion resistance**. These pipes undergo a specialized coating process, which provides a protective layer that extends their lifespan and performance in challenging environments. Understanding the specifications and functionalities of coated steel pipes is essential for any construction professional looking to make informed purchasing decisions.

Coated steel pipes come in various types, including **galvanized**, **polyethylene**, and **epoxy-coated** options. Each type offers unique benefits depending on the specific requirements of your project. For instance, galvanized pipes are ideal for outdoor applications due to their rust-resistant properties, while epoxy-coated pipes are well-suited for environments that require superior chemical resistance.

2. The Importance of Coating in Steel Pipes

The coating on steel pipes serves as a barrier against external elements that can lead to corrosion and degradation. **Corrosion** can significantly compromise the structural integrity of your construction, leading to costly repairs and safety hazards. Therefore, selecting a coated steel pipe with a quality coating is vital for ensuring the longevity and reliability of your infrastructure.

Moreover, the coating can also provide additional benefits such as improved aesthetics, reduced friction during installation, and enhanced performance in fluctuating temperatures. It is imperative to assess the specific needs of your project to determine the most appropriate coating type, which in turn influences your choice of supplier.

3. Key Factors to Consider When Choosing a Supplier

When embarking on the journey to select a supplier for coated steel pipes, several key factors need careful consideration:

3.1 Product Range and Specialization

Not all suppliers offer the same range of products. A supplier that specializes in coated steel pipes will likely have a more comprehensive selection and deeper expertise. Look for suppliers who can provide various coating options tailored to different applications.

3.2 Industry Experience

Experience plays a crucial role in supplier reliability. A supplier with years in the industry will have established processes for quality control, compliance with standards, and a reputation you can trust.

3.3 Customer Reviews and Testimonials

Feedback from previous customers can provide insights into the supplier’s reliability, product quality, and customer service. Seek out testimonials and case studies that reflect the supplier's ability to meet specific construction needs.

3.4 Geographic Location

The supplier's location can impact shipping times and costs. Choosing a supplier closer to your construction site may reduce transportation expenses and lead times, enhancing your project's efficiency.

4. Assessing Supplier Reliability and Credentials

Reliable suppliers will have proper credentials that can instill confidence in their products and services. Key aspects to verify include:

4.1 Certifications and Compliance

Ensure that the supplier adheres to industry standards and possesses relevant certifications. Certifications such as ISO 9001 indicate a commitment to quality management and consistent improvement.

4.2 Warranty and Return Policies

A reputable supplier will offer warranties on their products, providing peace of mind regarding quality and performance. Familiarize yourself with their return policies in case the products do not meet your specifications.

4.3 Transparency and Accountability

A trustworthy supplier should be open about their manufacturing processes, sourcing of materials, and pricing structures. Transparency fosters accountability and builds a relationship of trust.

5. The Role of Quality Control and Certifications

Quality assurance is non-negotiable when it comes to construction materials. Look for suppliers who implement rigorous quality control measures throughout their manufacturing processes.

5.1 Testing and Inspection

Inquire about the testing protocols that the supplier employs to ensure their products meet industry standards. Inspections should occur at various stages of production, from raw materials to finished products.

5.2 Compliance with Industry Standards

Ensure your supplier complies with local and international standards (e.g., ASTM, ASME) concerning steel pipes. Compliance guarantees that the products will meet the required performance criteria for your construction needs.

6. Evaluating Supplier Communication and Support

Effective communication is vital in any business relationship. A supplier should be accessible and responsive, providing clear information regarding product availability, lead times, and support for your technical inquiries.

6.1 Customer Service

Consider the level of customer service offered by the supplier. A dedicated support team can help address your concerns, assist with orders, and provide troubleshooting when necessary.

6.2 Technical Expertise

A knowledgeable supplier can offer valuable insights into the right products for your specific application, helping you make informed decisions. Look for suppliers who provide technical support and guidance.

7. Cost-Effectiveness and Pricing Strategies

While cost should not be the sole deciding factor, it is undoubtedly an important consideration. The objective is to find a supplier that offers a balance between quality and price.

7.1 Competitive Pricing

Research market rates and ensure your supplier offers competitive pricing without compromising on quality. Don't hesitate to ask for quotes from multiple suppliers for comparison.

7.2 Bulk Order Discounts

If you anticipate large orders, inquire about bulk discounts. Many suppliers offer price breaks for substantial purchases, contributing to overall project savings.

7.3 Total Cost of Ownership

Consider the total cost of ownership, which includes procurement, maintenance, and potential replacement costs over time. Investing in higher-quality coated steel pipes from a reputable supplier may result in greater long-term savings.

8. Frequently Asked Questions (FAQs)

8.1 What are the benefits of coated steel pipes?

Coated steel pipes provide enhanced corrosion resistance, increased durability, and improved lifespan in challenging environments. They also offer aesthetic advantages and can reduce maintenance costs.

8.2 How do I determine the right coating type for my project?

The coating type depends on the environmental conditions and specific application needs. Consider factors like exposure to moisture, chemicals, and temperature fluctuations when selecting the right coating.

8.3 Are there different grades of coated steel pipes?

Yes, coated steel pipes are available in various grades, each designed for different applications. The grade you choose should align with your project's requirements and local building codes.

8.4 How can I verify a supplier's quality control practices?

Request documentation of the supplier's quality control processes, including certifications, testing methodologies, and compliance with industry standards.

8.5 What should I do if I receive defective products?

Contact your supplier immediately to report any issues. Reputable suppliers will typically have return policies and procedures in place for defective products.

9. Conclusion

Choosing the right coated steel pipe supplier is a critical step in ensuring the success of your construction projects. By understanding the importance of coated steel pipes, assessing potential suppliers based on reliability, quality control, and communication, you can make informed decisions that ultimately contribute to the durability and performance of your builds.

Investing time in selecting a reputable coated steel pipe supplier not only enhances the quality of your construction but also ensures that you receive the support and expertise necessary to navigate the complexities of your project. Take these considerations to heart, and you will be well on your way to sourcing the best materials for your construction needs.

TAG:

Related Posts

Choosing the Right Coated Steel Pipe Supplier for Your Construction Needs

Choosing the Right Coated Steel Pipe Supplier for Your Construction Needs

Table of Contents

1. Understanding Coated Steel Pipes

2. The Importance of Coating in Steel Pipes

3. Key Factors to Consider When Choosing a Supplier

4. Assessing Supplier Reliability and Credentials

5. The Role of Quality Control and Certifications

6. Evaluating Supplier Communication and Support