Contact us

E-mail: dong@cnhtpipes.com

Phone: +86-19131787770

WhatsApp: +8619131787770

Wuliyao Industrial Zone, Yanshan County, Cangzhou City, Hebei Province, China

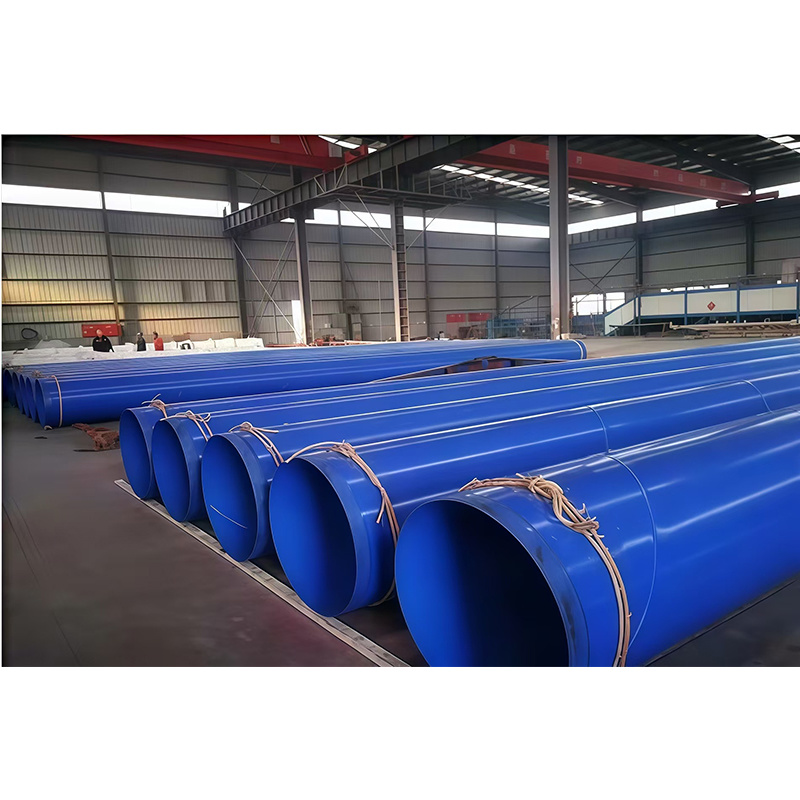

Plastic-Coated steel Pipe

- Description

-

Plastic-coated steel pipe, also known as plastic-coated steel composite pipe, is a kind of composite pipe that combines the advantages of steel pipe and plastic pipe. The following is an introduction to it:

Structure and Manufacturing Process

Structure: It takes steel pipe as the base pipe and applies a plastic anti-corrosion layer on the inner surface or both the inner and outer surfaces through processes like spraying, rolling, soaking, or suction.

Manufacturing Process:

Steel Pipe Preparation: The steel pipe undergoes surface treatment such as rust removal and cleaning to ensure good adhesion of the coating.

Heating and Coating: The treated steel pipe is heated to a certain temperature, and then plastic powder or liquid coating is applied evenly on the inner and outer surfaces of the steel pipe by spraying or dipping.

Curing: The coating is cured by heating or natural cooling to make it adhere firmly to the steel pipe surface, forming a uniform and dense coating.

Advantages

Excellent Corrosion Resistance: The plastic coating isolates the steel pipe from the outside environment, preventing the steel pipe from being corroded by water, air, and corrosive substances, thus prolonging the service life.

Good Mechanical Properties: It retains the high strength and high pressure-bearing capacity of the steel pipe, being able to withstand greater external forces and internal pressures.

Low Friction Resistance: The plastic coating has a smooth surface, which can reduce fluid resistance, prevent scaling and sedimentation, and improve the efficiency of fluid transportation.

Good Insulation Performance: It can be used as a protective tube for wires and cables, effectively shielding external signal interference and preventing leakage.

Convenient Installation: It is lighter in weight and easier to connect compared to ordinary steel pipes, reducing construction difficulty and cost.

Standards

Domestic Standards: Common standards include CJ/T 120-2008 "Technical Specification for Epoxy Resin Coated Steel Pipes for Water Supply and Drainage", which specifies the technical requirements, test methods, inspection rules, etc. of epoxy resin coated steel pipes for water supply and drainage.

International Standards: Such as AWWA C210, which is an American standard specifying the requirements for polyethylene-coated steel pipes used in water supply systems.

Sizes

Outer Diameter: Usually ranges from 34mm to 2540mm.

Wall Thickness: There is a wide range of wall thicknesses available to meet different pressure and usage requirements.

Length: The common length is 6m, 9m, 12m, etc., and can also be customized according to customer requirements.

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!