Contact us

E-mail: dong@cnhtpipes.com

Phone: +86-19131787770

WhatsApp: +8619131787770

Wuliyao Industrial Zone, Yanshan County, Cangzhou City, Hebei Province, China

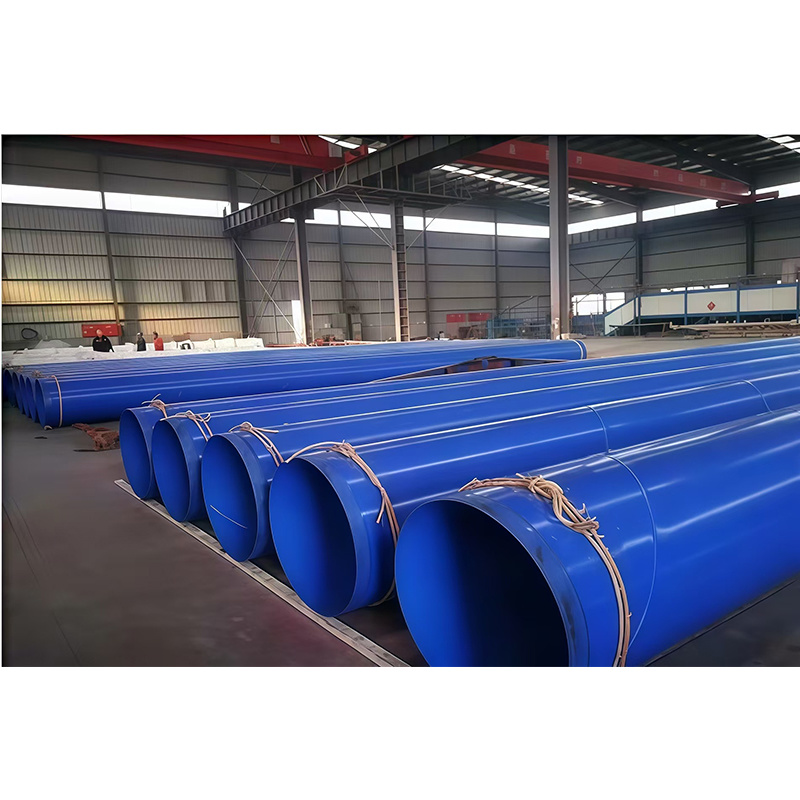

3PE Steel Pipe

- Description

-

3PE steel pipe, short for three-layer polyethylene anti-corrosive steel pipe, is a type of steel pipe with excellent anti-corrosion performance. The following is a detailed introduction:

Structure

The anti-corrosion layer of 3PE steel pipe is composed of three layers:

First layer: Epoxy powder layer (FBE >100um). It has good adhesion to the steel pipe surface and provides a strong anti-corrosion foundation with excellent chemical resistance and adhesion.

Second layer: Adhesive layer (170-250um). It is a copolymer adhesive with branched functional groups, which can firmly bond the epoxy powder layer and the polyethylene layer, playing a role in connection and fixation.

Third layer: Polyethylene layer (1.8-3.7mm). Usually made of high-density polyethylene, it has good physical properties such as wear resistance, impact resistance and water resistance, providing physical protection for the steel pipe.

Advantages

Excellent Corrosion Resistance: The combination of the three layers forms a dense anti-corrosion barrier, effectively isolating the steel pipe from the erosion of external media such as water, oxygen and corrosive substances, thus greatly prolonging the service life of the steel pipe.

Good Sealing Performance: It has a high degree of sealing, which can prevent the leakage of the conveyed medium and the infiltration of external substances, ensuring the safety and stability of the pipeline transportation.

High Mechanical Strength: The polyethylene layer has high strength and toughness, and together with the epoxy powder layer and the adhesive layer, it endows the steel pipe with strong resistance to external forces such as pressure and impact.

Strong Low-Temperature Resistance: It has good flexibility and anti-impact performance at low temperatures, and can be used normally in cold environments without being prone to brittle fracture.

Convenient Construction: It is easy to install and construct. The surface of the steel pipe is smooth, which is convenient for transportation and laying, and can improve the construction efficiency.

Applications

Oil and Gas Industry: It is widely used in the transportation of oil and natural gas, such as oil and gas gathering pipelines, long-distance transmission pipelines and submarine pipelines, which can effectively prevent the corrosion of steel pipes and ensure the safe and stable transportation of oil and gas.

Chemical Industry: It is suitable for the transportation of various corrosive media in the chemical industry, such as acid-base solutions, organic solvents, etc., which can resist the erosion of chemical substances and ensure the normal operation of the pipeline system.

Water Supply and Drainage Projects: It can be used for water supply pipelines in urban water supply projects and drainage pipelines in sewage treatment projects, which can resist the corrosion of water and sewage and improve the service life of the pipeline.

Heat Supply Projects: In district heating projects, it is used to transport hot water or steam, which can not only resist corrosion but also have a certain heat preservation effect, reducing heat loss.

Standards

Domestic Standards: SY/T0413-2002, which mainly standardizes polyethylene and high-density polyethylene, with the Vicat softening point set at not less than 110°C. GB/T 23257-2009 "Technical Specifications for Three-Layer Polyethylene Fatty Acid Copolymer Coating for External Anti-Corrosion Steel Pipes".

International Standards: DIN 30670, CAN/CSA-Z245.21, NFA 49-710, ISO DIS 21809-1.

Sizes

Nominal Diameter: DN50-DN2200.

Outer Diameter: 219.1mm - 4064mm (8"-160").

Wall Thickness: 3.2mm - 40mm.

Length: 6m - 18m.

Key words:

Inquire Now

Note: Please leave your email address, our professionals will contact you as soon as possible!