Discover the Unmatched Benefits of 3PE Anti-Corrosion Steel Pipe in Construction

Jul 14,2025

Discover the Unmatched Benefits of 3PE Anti-Corrosion Steel Pipe in Construction

Table of Contents

Introduction to 3PE Anti-Corrosion Steel Pipes

What is 3PE Coating?

The Importance of Anti-Corrosion Solutions in Construction

Benefits of 3PE Anti-Corrosion Steel Pipes

1. Durability and Longevity

2. Cost-Effectiveness

3. Environmental Im

Discover the Unmatched Benefits of 3PE Anti-Corrosion Steel Pipe in Construction

Table of Contents

- Introduction to 3PE Anti-Corrosion Steel Pipes

- What is 3PE Coating?

- The Importance of Anti-Corrosion Solutions in Construction

- Benefits of 3PE Anti-Corrosion Steel Pipes

- 1. Durability and Longevity

- 2. Cost-Effectiveness

- 3. Environmental Impact

- 4. Installation Convenience

- 5. Customization Options

- Applications of 3PE Anti-Corrosion Steel Pipes

- Maintenance Tips for 3PE Pipes

- Frequently Asked Questions

- Conclusion

Introduction to 3PE Anti-Corrosion Steel Pipes

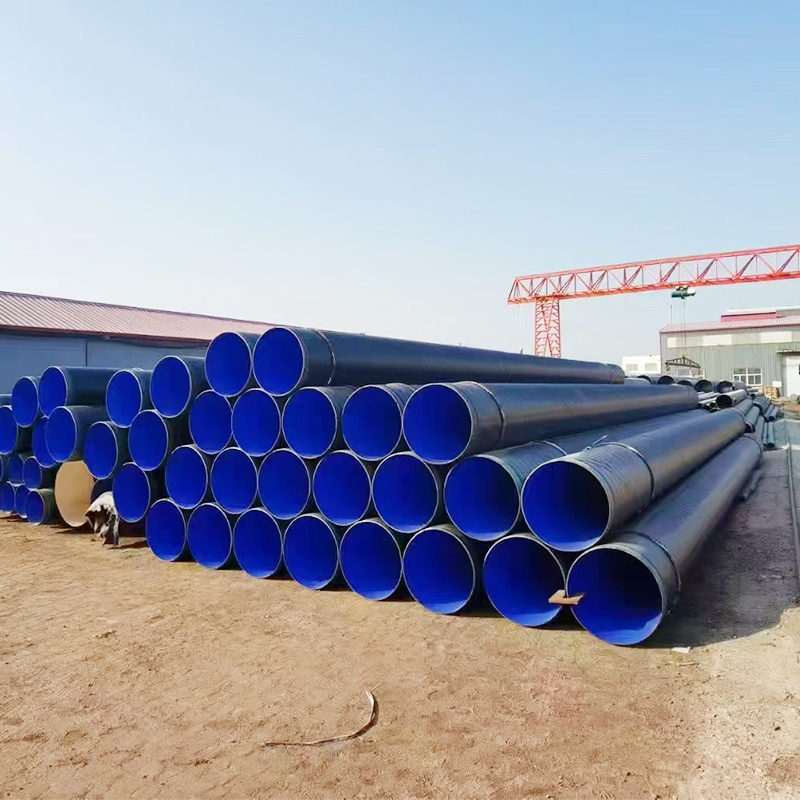

The construction industry continuously seeks innovative materials that enhance durability while minimizing maintenance costs. The **3PE (three-layer polyethylene)** anti-corrosion steel pipe has emerged as a game changer. With its advanced protective features, it offers an effective solution for combating corrosion, extending the lifespan of pipelines in various construction applications.

What is 3PE Coating?

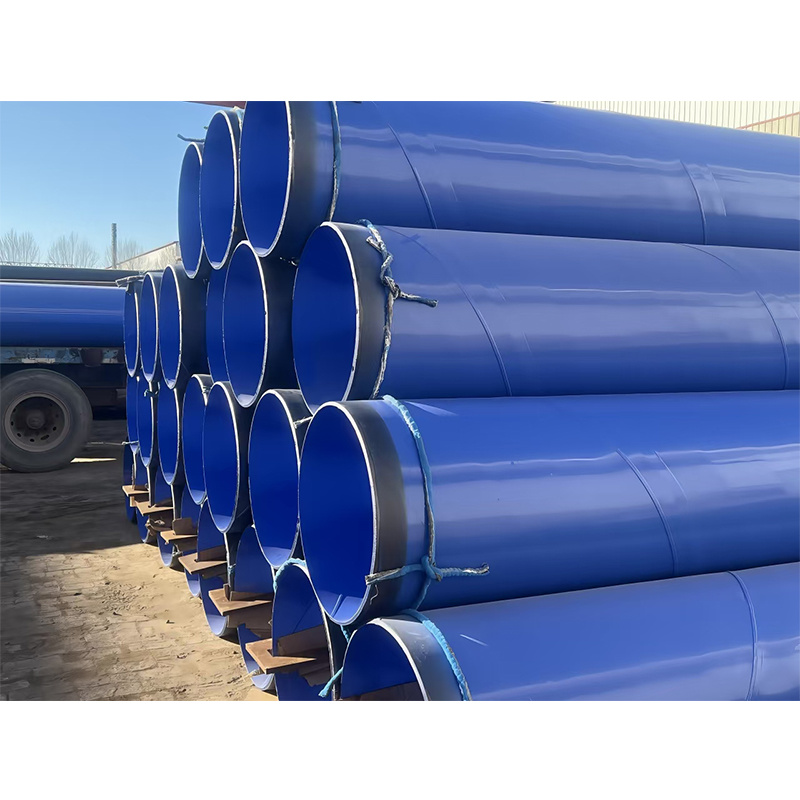

3PE coating consists of three distinct layers:

1. **The First Layer**: An epoxy primer that creates a strong adhesive bond to the steel surface, ensuring optimal adhesion and corrosion resistance.

2. **The Second Layer**: A middle layer of adhesive that serves to enhance the bond between the inner steel pipe and the outer polyethylene layer.

3. **The Third Layer**: A thick layer of polyethylene that provides robust protection against physical damage and environmental factors.

This innovative coating technique significantly enhances the pipe's resistance to corrosion, making it ideal for use in various harsh environments, including underground and offshore applications.

The Importance of Anti-Corrosion Solutions in Construction

Corrosion is one of the most significant challenges faced by the construction industry, particularly concerning metal structures and pipelines. It leads to material degradation, compromised structural integrity, and costly repairs. Incorporating anti-corrosion solutions like 3PE coatings is essential to protect investments and ensure the longevity of construction projects.

By choosing effective corrosion protection, construction professionals can minimize failures, reduce maintenance costs, and enhance overall project safety.

Benefits of 3PE Anti-Corrosion Steel Pipes

The adoption of **3PE anti-corrosion steel pipes** offers a multitude of advantages in the construction sector. Here, we delve into the key benefits:

1. Durability and Longevity

3PE-coated steel pipes exhibit remarkable durability, resisting wear and tear from harsh environmental conditions. The combination of corrosion resistance and physical protection ensures these pipes can last decades without significant degradation. This extended lifespan reduces the need for frequent replacements, contributing to long-term cost savings.

2. Cost-Effectiveness

While the initial investment in 3PE-coated pipes may be higher than standard steel pipes, the long-term savings are substantial. The reduced maintenance and replacement costs can lead to significant financial advantages over the life of the installation. In addition, fewer service interruptions mean more efficient project timelines and increased productivity.

3. Environmental Impact

3PE anti-corrosion pipes are designed with sustainability in mind. Their longevity reduces the frequency of pipe replacements, resulting in less waste and lower carbon footprints. Furthermore, the protective coating prevents leaks, safeguarding surrounding ecosystems from contamination due to hazardous substances.

4. Installation Convenience

The lightweight nature of 3PE pipes simplifies handling and installation, making them an ideal choice for complex construction projects. Their compatibility with various fittings and supports simplifies the construction process and minimizes installation time.

5. Customization Options

3PE anti-corrosion steel pipes can be customized to meet specific project requirements. Various pipe diameters, wall thicknesses, and coatings can be tailored to suit different applications, enabling construction professionals to optimize performance and efficiency.

Applications of 3PE Anti-Corrosion Steel Pipes

3PE anti-corrosion steel pipes are utilized across various sectors, including:

- **Water Supply Systems**: Ensuring safe and reliable water distribution.

- **Oil and Gas Pipelines**: Protecting against harsh environmental conditions and corrosive substances.

- **Sewage Systems**: Enhancing the lifespan of wastewater management infrastructure.

- **Industrial Applications**: Providing durability in manufacturing and processing environments.

These versatile applications underscore the importance of 3PE technology in modern construction projects.

Maintenance Tips for 3PE Pipes

While 3PE anti-corrosion steel pipes require minimal maintenance due to their robust design, some simple practices can extend their lifespan even further:

1. **Regular Inspections**: Conduct routine checks for any signs of damage or wear.

2. **Proper Installation**: Ensure pipes are installed according to industry standards to prevent premature failure.

3. **Cleaning**: Regularly clean the exterior to remove debris and potential contaminants that could affect performance.

4. **Monitoring**: Keep an eye on surrounding environmental factors that could impact the integrity of the pipes, such as soil composition and moisture levels.

By following these maintenance practices, construction professionals can ensure the optimal performance of 3PE anti-corrosion steel pipes.

Frequently Asked Questions

1. What is the lifespan of 3PE anti-corrosion steel pipes?

The lifespan of 3PE anti-corrosion steel pipes can exceed 50 years, depending on the environmental conditions and maintenance practices.

2. How do 3PE pipes compare to traditional steel pipes?

3PE pipes offer superior corrosion resistance, durability, and longevity compared to traditional steel pipes, which may require frequent maintenance and replacement.

3. Are 3PE anti-corrosion pipes environmentally friendly?

Yes, their extended lifespan and leak prevention capabilities contribute to reduced environmental impact, making them a sustainable choice for construction projects.

4. Can 3PE pipes be used in extreme weather conditions?

Absolutely. 3PE anti-corrosion steel pipes are designed to withstand harsh weather and environmental conditions, making them suitable for a wide range of applications.

5. What industries benefit most from 3PE anti-corrosion pipes?

Industries such as water supply, oil and gas, sewage management, and various manufacturing sectors benefit significantly from the use of 3PE anti-corrosion steel pipes due to their durability and resistance to corrosion.

Conclusion

The adoption of **3PE anti-corrosion steel pipes** marks a significant advancement in construction materials, providing unparalleled durability, cost-effectiveness, and environmental benefits. As construction professionals increasingly recognize the long-term advantages of incorporating these innovative pipes into their projects, they pave the way for safer, more efficient, and sustainable building practices. Understanding the myriad benefits of 3PE technology equips industry stakeholders with the knowledge necessary to make informed decisions that enhance the longevity and reliability of their construction investments.

TAG:

Previous

Related Posts

Discover the Unmatched Benefits of 3PE Anti-Corrosion Steel Pipe in Construction

Discover the Unmatched Benefits of 3PE Anti-Corrosion Steel Pipe in Construction

Table of Contents

Introduction to 3PE Anti-Corrosion Steel Pipes

What is 3PE Coating?

The Importance of Anti-Corrosion Solutions in Construction

Benefits of 3PE Anti-Corrosion Steel Pipes

1. Durability and Longevity

2. Cost-Effectiveness

3. Environmental Im