Why Choosing Insulated Pipes is Essential for Efficient District Heating Supply

Jun 16,2025

Why Choosing Insulated Pipes is Essential for Efficient District Heating Supply

Understanding District Heating Systems

District heating refers to the centralized production and distribution of heat to multiple buildings from a single source. This system is commonly used in urban areas where heating demands are high. The efficiency of such systems greatly depends on the materials used for heat dist

Why Choosing Insulated Pipes is Essential for Efficient District Heating Supply

Understanding District Heating Systems

District heating refers to the centralized production and distribution of heat to multiple buildings from a single source. This system is commonly used in urban areas where heating demands are high. The efficiency of such systems greatly depends on the materials used for heat distribution, particularly piping.

What Are Insulated Pipes?

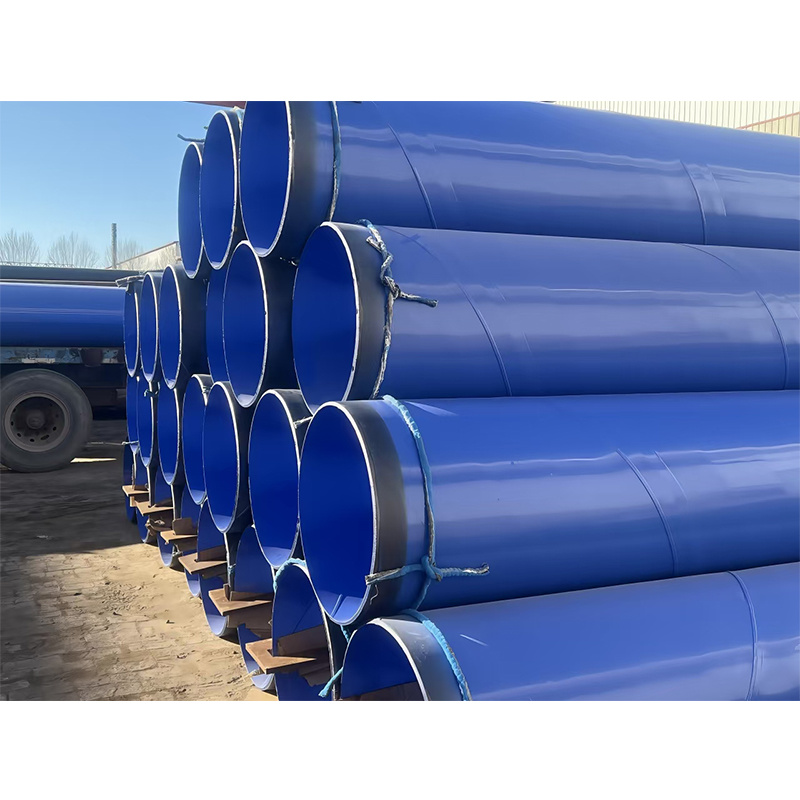

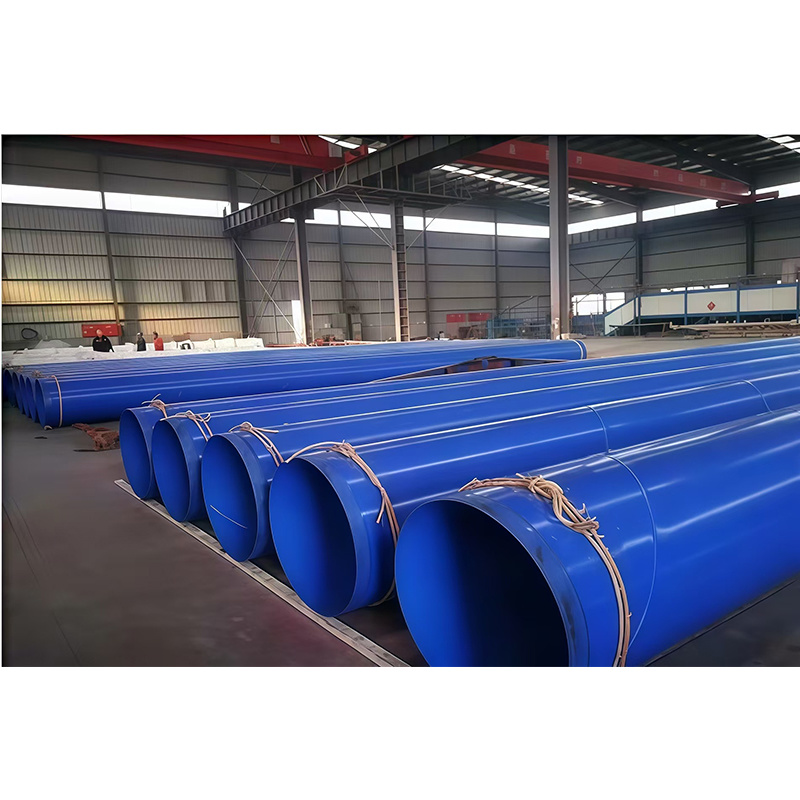

Insulated pipes are designed with layers of insulation that reduce heat loss as hot water travels from the heating source to consumers. These pipes are crafted to provide optimal thermal performance, ensuring that energy is not wasted during transmission.

The Importance of Insulated Pipes in District Heating

When it comes to district heating, the choice of pipes can significantly affect overall system efficiency. Insulated pipes play a crucial role in maintaining high temperatures while minimizing energy loss, which in turn translates to cost savings and environmental benefits.

Key Benefits of Using Insulated Pipes

Understanding why insulated pipes are essential involves examining their numerous benefits, which include:

1. Enhanced Energy Efficiency

One of the primary advantages of insulated pipes is their ability to **increase energy efficiency**. By minimizing heat loss, these pipes ensure that more energy reaches the end-user, reducing the need for excess fuel consumption. This efficiency is particularly important in large-scale heating systems where even small losses can lead to significant energy waste.

2. Cost Savings on Energy Bills

With reduced heat loss comes lower energy bills. By implementing insulated pipes in district heating systems, operators can realize substantial financial savings over time. The initial investment in insulated piping may be offset by the reduced operational costs associated with energy consumption.

3. Environmental Benefits

Using insulated pipes contributes to a reduction in greenhouse gas emissions. By enhancing the efficiency of district heating systems, these pipes help lower the carbon footprint associated with heating. This aligns with global efforts to combat climate change and promote sustainable energy practices.

4. Improved System Longevity

Insulated pipes are designed to withstand harsh environmental conditions. Their robust construction ensures durability, which means fewer repairs and replacements over time. This longevity contributes to the overall sustainability of the heating system.

5. Versatility in Applications

Insulated pipes can be used in a variety of applications beyond district heating, including industrial processes and residential heating. This versatility makes them a valuable investment for multiple sectors.

Types of Insulated Pipes for District Heating

Different types of insulated pipes cater to various needs in district heating systems. Understanding these options is crucial for making an informed choice.

1. Pre-insulated Pipes

Pre-insulated pipes come with insulation already applied, making installation simpler and more efficient. These pipes are often used in modern district heating systems and are designed to provide excellent thermal performance.

2. Foam Insulated Pipes

Foam insulated pipes use polyurethane foam for insulation, offering high thermal resistance. This type of insulation helps minimize heat loss and is suitable for various temperature ranges.

3. Mineral Wool Insulated Pipes

Mineral wool insulated pipes are known for their fire-resistant properties. They provide effective insulation while also enhancing safety in heating applications.

Factors to Consider When Choosing Insulated Pipes

Selecting the right insulated pipes for a district heating system requires careful consideration of several factors:

1. Temperature Requirements

Different applications may have varying temperature requirements. It’s essential to choose insulated pipes that can withstand the necessary operating temperatures without compromising performance.

2. Pipe Sizing

Proper sizing is critical to ensure optimal flow rates and pressure in the heating system. Oversized or undersized pipes can lead to inefficiencies, so consulting with an expert during the selection process is advisable.

3. Material Compatibility

The materials used for insulated pipes should be compatible with the heating fluid. This compatibility helps prevent corrosion and extends the lifespan of the piping system.

4. Installation Conditions

The installation environment can impact the performance of insulated pipes. Factors such as soil type, temperature variations, and potential physical stresses should be considered to ensure long-term reliability.

Installation Best Practices for Insulated Pipes

Proper installation of insulated pipes is crucial to maximizing their effectiveness and ensuring the longevity of the district heating system.

1. Planning and Design

Before installation, a detailed plan should be developed that outlines the layout and specific requirements of the heating system. This will help identify the best piping routes and installation techniques.

2. Professional Installation

Engaging professional installers with experience in district heating systems can significantly reduce the risk of installation errors. Their expertise ensures that insulated pipes are installed correctly and function optimally.

3. Regular Maintenance Checks

Conducting regular maintenance checks on insulated pipes is essential for identifying potential issues early on. This proactive approach can prevent costly repairs and downtime.

Cost Considerations for Insulated Pipes

The initial investment in insulated pipes can be higher than standard piping options, but the long-term benefits often outweigh these costs.

1. Initial Investment vs. Long-Term Savings

While insulated pipes may come with a higher upfront cost, their ability to reduce energy consumption and maintenance costs can lead to significant savings over the lifespan of the system.

2. Lifecycle Cost Analysis

Performing a lifecycle cost analysis helps stakeholders understand the total costs associated with insulated pipes, including installation, operation, maintenance, and replacement.

FAQs about Insulated Pipes in District Heating

1. What are insulated pipes made of?

Insulated pipes can be made from various materials, including polyethylene, steel, and reinforced plastic, depending on the specific application and temperature requirements.

2. How do insulated pipes reduce heat loss?

The insulation around the pipes acts as a barrier, preventing heat from escaping into the surrounding environment during the transportation of hot fluids.

3. Can insulated pipes be used for both heating and cooling applications?

Yes, insulated pipes can be utilized for both heating and cooling systems, making them versatile for various applications.

4. What maintenance is required for insulated pipes?

Regular inspections are recommended to check for any signs of damage, leaks, or wear. Ensuring that insulation remains intact is crucial for maintaining efficiency.

5. Are there specific regulations for using insulated pipes in district heating?

Yes, there are guidelines and regulations that vary by location. It’s essential to consult local codes and standards when installing insulated pipes for district heating systems.

Conclusion

Choosing insulated pipes for district heating systems is essential for maximizing energy efficiency, lowering costs, and promoting sustainability. The benefits of enhanced thermal performance, reduced environmental impact, and improved system longevity make insulated pipes a crucial investment for efficient district heating supply. By considering the types, installation practices, and cost analyses associated with insulated pipes, stakeholders can make informed decisions that contribute to the success of their heating systems.

Related Posts

Custom Insulated Pipes for Oil and Gas: Enhancing Efficiency and Safety

In the oil and gas industry, the transportation of fluids is a critical process that requires specialized materials and technologies. One of the key innovations in this realm is the use of insulated pipes for oil and gas. These pipes are designed to minimize heat loss, prevent condensation, and maintain the integrity of the fluids being transported. Customization plays a significant role in optimi