Custom Insulated Pipes for Oil and Gas: Enhancing Efficiency and Safety

Jun 17,2025

In the oil and gas industry, the transportation of fluids is a critical process that requires specialized materials and technologies. One of the key innovations in this realm is the use of insulated pipes for oil and gas. These pipes are designed to minimize heat loss, prevent condensation, and maintain the integrity of the fluids being transported. Customization plays a significant role in optimi

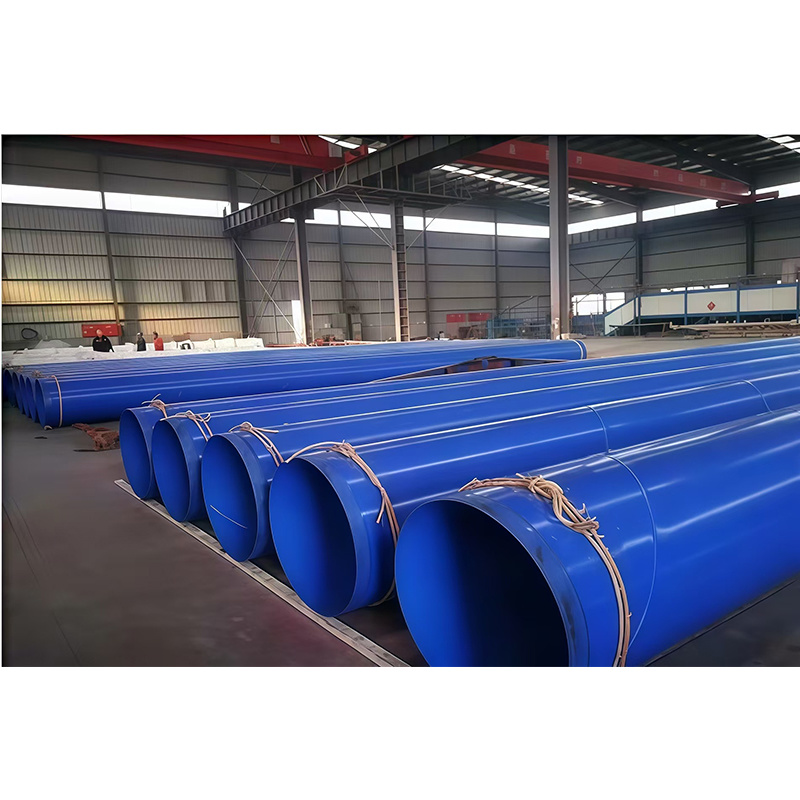

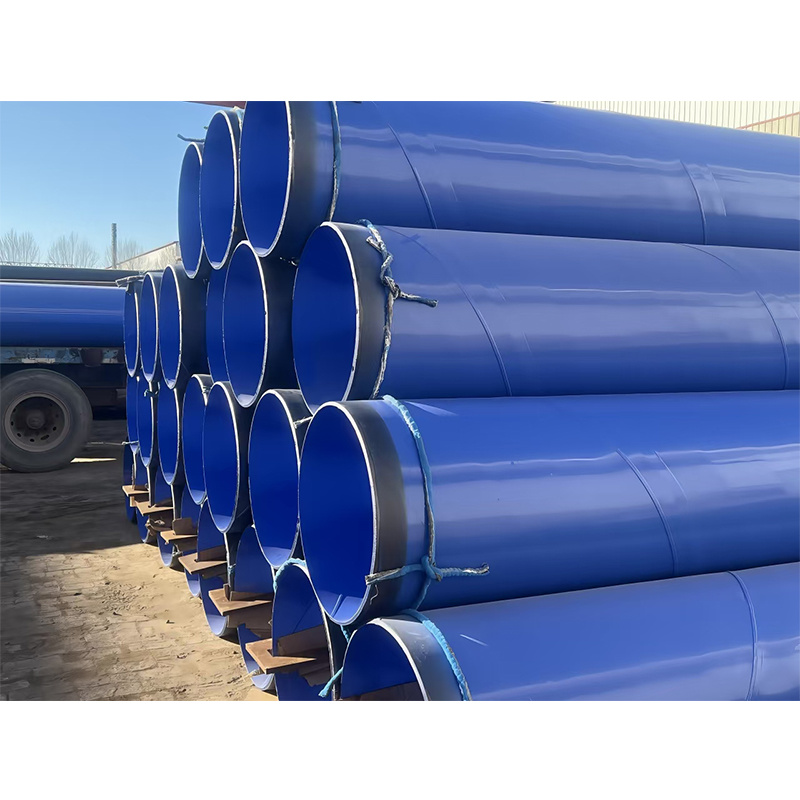

In the oil and gas industry, the transportation of fluids is a critical process that requires specialized materials and technologies. One of the key innovations in this realm is the use of insulated pipes for oil and gas. These pipes are designed to minimize heat loss, prevent condensation, and maintain the integrity of the fluids being transported. Customization plays a significant role in optimizing these insulated pipes to meet the specific needs of various applications.

Insulated pipes typically feature a layer of thermal insulation that surrounds the pipe’s exterior. This insulation serves several purposes, particularly in maintaining the temperature of the transported substances, which can be vital for the efficiency of operations. For instance, when transporting crude oil or natural gas, maintaining a consistent temperature helps prevent the fluid from solidifying or degrading. Customized solutions allow for the selection of insulation materials, thickness, and pipe diameter that directly align with operational requirements.

Moreover, the oil and gas industry often operates in extreme environments, where temperature fluctuations can be significant. Customized insulated pipes can be engineered to withstand harsh conditions, including high pressures and corrosive elements. This customization ensures longevity and reduces the need for frequent maintenance or replacements, ultimately leading to cost savings and enhanced operational efficiency.

Another critical aspect of insulated pipes for oil and gas is their role in safety. Insulation can help in reducing the risk of leaks and spills by preventing condensation from forming on the pipe's surface, which can lead to hazardous situations. Custom designs can incorporate features such as protective coatings or specific geometries that enhance safety measures. This is particularly important in offshore applications, where environmental protection is paramount.

Customization also extends to the manufacturing processes used for these insulated pipes. Different projects may require unique specifications, such as specific diameters, lengths, or connection types. By focusing on a custom approach, manufacturers can ensure that the insulated pipes meet the exact requirements of the project, leading to better integration within existing systems.

In conclusion, insulated pipes for oil and gas, particularly when customized, offer numerous benefits including improved thermal efficiency, enhanced safety, and reduced maintenance costs. As the industry continues to evolve, the demand for tailored solutions that meet specific operational needs will only increase. Investing in customized insulated piping systems is a strategic choice for companies looking to enhance their operational efficiency while prioritizing safety and environmental protection. Understanding the value of these pipes can lead to significant advancements in the transportation of fluids within the oil and gas sector.

Insulated pipes typically feature a layer of thermal insulation that surrounds the pipe’s exterior. This insulation serves several purposes, particularly in maintaining the temperature of the transported substances, which can be vital for the efficiency of operations. For instance, when transporting crude oil or natural gas, maintaining a consistent temperature helps prevent the fluid from solidifying or degrading. Customized solutions allow for the selection of insulation materials, thickness, and pipe diameter that directly align with operational requirements.

Moreover, the oil and gas industry often operates in extreme environments, where temperature fluctuations can be significant. Customized insulated pipes can be engineered to withstand harsh conditions, including high pressures and corrosive elements. This customization ensures longevity and reduces the need for frequent maintenance or replacements, ultimately leading to cost savings and enhanced operational efficiency.

Another critical aspect of insulated pipes for oil and gas is their role in safety. Insulation can help in reducing the risk of leaks and spills by preventing condensation from forming on the pipe's surface, which can lead to hazardous situations. Custom designs can incorporate features such as protective coatings or specific geometries that enhance safety measures. This is particularly important in offshore applications, where environmental protection is paramount.

Customization also extends to the manufacturing processes used for these insulated pipes. Different projects may require unique specifications, such as specific diameters, lengths, or connection types. By focusing on a custom approach, manufacturers can ensure that the insulated pipes meet the exact requirements of the project, leading to better integration within existing systems.

In conclusion, insulated pipes for oil and gas, particularly when customized, offer numerous benefits including improved thermal efficiency, enhanced safety, and reduced maintenance costs. As the industry continues to evolve, the demand for tailored solutions that meet specific operational needs will only increase. Investing in customized insulated piping systems is a strategic choice for companies looking to enhance their operational efficiency while prioritizing safety and environmental protection. Understanding the value of these pipes can lead to significant advancements in the transportation of fluids within the oil and gas sector.

TAG:

Related Posts

Custom Insulated Pipes for Oil and Gas: Enhancing Efficiency and Safety

In the oil and gas industry, the transportation of fluids is a critical process that requires specialized materials and technologies. One of the key innovations in this realm is the use of insulated pipes for oil and gas. These pipes are designed to minimize heat loss, prevent condensation, and maintain the integrity of the fluids being transported. Customization plays a significant role in optimi