Understanding 3PE Anti-Corrosion Pipes: A Comprehensive Guide

Jul 17,2025

---

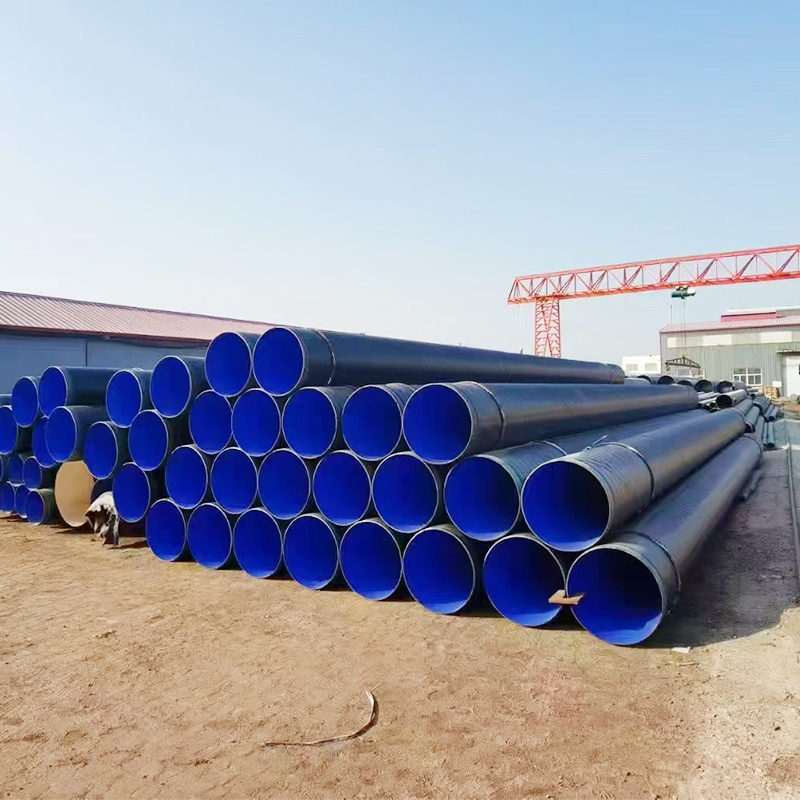

3PE anti-corrosion pipes, or three-layer polyethylene anti-corrosion pipes, are specialized pipelines designed to resist corrosion and extend the lifespan of infrastructure in various industrial applications. These pipes are constructed using a unique three-layer system consisting of an epoxy primer, a copolymer adhesive, and a high-density polyethylene (HDPE) outer layer. This innovative cons

---

3PE anti-corrosion pipes, or three-layer polyethylene anti-corrosion pipes, are specialized pipelines designed to resist corrosion and extend the lifespan of infrastructure in various industrial applications. These pipes are constructed using a unique three-layer system consisting of an epoxy primer, a copolymer adhesive, and a high-density polyethylene (HDPE) outer layer. This innovative construction offers superior protection against environmental factors, making them ideal for use in harsh conditions.

The first layer, an epoxy primer, serves as a strong adhesive that bonds the subsequent layers to the steel pipe. This layer is crucial as it offers excellent adhesion properties and serves as a barrier against moisture and corrosive elements. The second layer, the copolymer adhesive, enhances the bond between the epoxy and the outer polyethylene, further ensuring that the protective layers remain intact even under stress. Finally, the HDPE outer layer provides a durable shield against physical abrasions, UV radiation, and chemical exposure, making the pipes resilient to a wide range of environmental conditions.

One of the significant advantages of 3PE anti-corrosion pipes is their ability to significantly reduce maintenance costs associated with corrosion. In traditional pipelines, corrosion can lead to leaks, structural failure, and increased operational costs. By employing 3PE technology, industries can minimize the risk of corrosion-related incidents, ensuring a safer and more efficient operation. This is particularly beneficial in industries such as oil and gas, water distribution, and chemical processing, where pipeline integrity is paramount.

Additionally, 3PE pipes are lightweight and easy to install, making them a practical choice for various applications. Their corrosion resistance not only extends the pipe's lifespan but also enhances the overall efficiency of the system by maintaining consistent flow rates and reducing the likelihood of blockages.

In terms of environmental impact, 3PE anti-corrosion pipes are designed with sustainability in mind. The materials used in their construction are recyclable, which contributes to a reduced environmental footprint. By opting for these pipes, industries are not only investing in longevity and reliability but are also making a responsible choice for the planet.

In conclusion, 3PE anti-corrosion pipes represent a significant advancement in pipeline technology. Their three-layer construction provides unmatched resistance to corrosion, ultimately leading to lower maintenance costs and enhanced system performance. As industries continue to seek durable and efficient solutions for their piping needs, 3PE anti-corrosion technology stands out as a reliable option that addresses both operational and environmental concerns.

3PE anti-corrosion pipes, or three-layer polyethylene anti-corrosion pipes, are specialized pipelines designed to resist corrosion and extend the lifespan of infrastructure in various industrial applications. These pipes are constructed using a unique three-layer system consisting of an epoxy primer, a copolymer adhesive, and a high-density polyethylene (HDPE) outer layer. This innovative construction offers superior protection against environmental factors, making them ideal for use in harsh conditions.

The first layer, an epoxy primer, serves as a strong adhesive that bonds the subsequent layers to the steel pipe. This layer is crucial as it offers excellent adhesion properties and serves as a barrier against moisture and corrosive elements. The second layer, the copolymer adhesive, enhances the bond between the epoxy and the outer polyethylene, further ensuring that the protective layers remain intact even under stress. Finally, the HDPE outer layer provides a durable shield against physical abrasions, UV radiation, and chemical exposure, making the pipes resilient to a wide range of environmental conditions.

One of the significant advantages of 3PE anti-corrosion pipes is their ability to significantly reduce maintenance costs associated with corrosion. In traditional pipelines, corrosion can lead to leaks, structural failure, and increased operational costs. By employing 3PE technology, industries can minimize the risk of corrosion-related incidents, ensuring a safer and more efficient operation. This is particularly beneficial in industries such as oil and gas, water distribution, and chemical processing, where pipeline integrity is paramount.

Additionally, 3PE pipes are lightweight and easy to install, making them a practical choice for various applications. Their corrosion resistance not only extends the pipe's lifespan but also enhances the overall efficiency of the system by maintaining consistent flow rates and reducing the likelihood of blockages.

In terms of environmental impact, 3PE anti-corrosion pipes are designed with sustainability in mind. The materials used in their construction are recyclable, which contributes to a reduced environmental footprint. By opting for these pipes, industries are not only investing in longevity and reliability but are also making a responsible choice for the planet.

In conclusion, 3PE anti-corrosion pipes represent a significant advancement in pipeline technology. Their three-layer construction provides unmatched resistance to corrosion, ultimately leading to lower maintenance costs and enhanced system performance. As industries continue to seek durable and efficient solutions for their piping needs, 3PE anti-corrosion technology stands out as a reliable option that addresses both operational and environmental concerns.

TAG:

Related Posts

Understanding 3PE Anti-Corrosion Pipes: A Comprehensive Guide

---

3PE anti-corrosion pipes, or three-layer polyethylene anti-corrosion pipes, are specialized pipelines designed to resist corrosion and extend the lifespan of infrastructure in various industrial applications. These pipes are constructed using a unique three-layer system consisting of an epoxy primer, a copolymer adhesive, and a high-density polyethylene (HDPE) outer layer. This innovative cons