Understanding Plastic-Coated Steel Pipes for Underground Utilities

Sep 21,2025

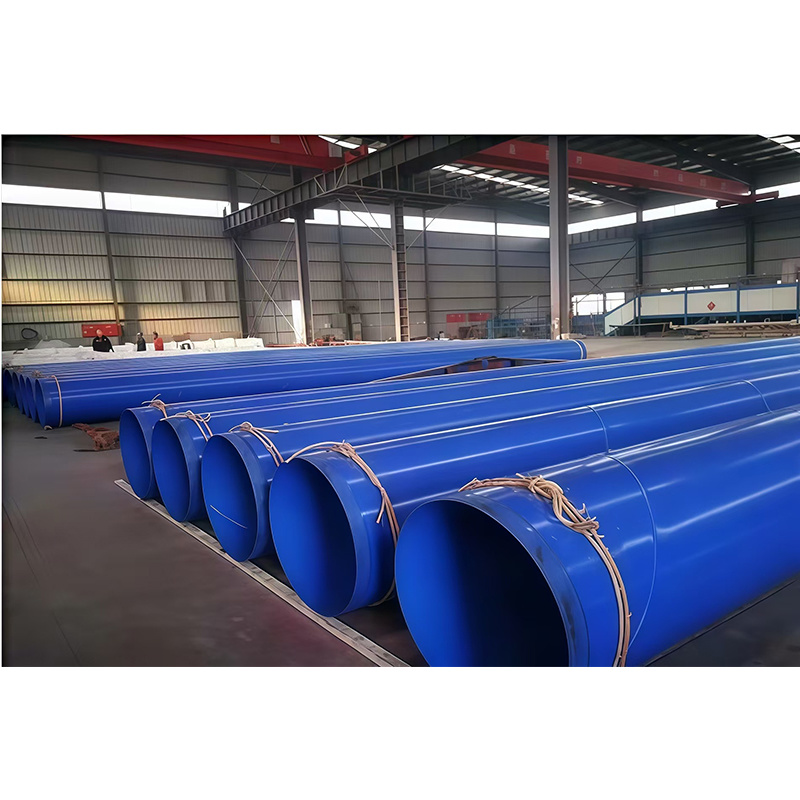

Plastic-coated steel pipes have become increasingly popular in the construction industry, particularly for underground utilities. These pipes are designed to provide enhanced protection and durability while meeting the needs of various applications, including water supply, gas distribution, and telecommunications. By understanding the characteristics and benefits of plastic-coated steel pipes, pro

Plastic-coated steel pipes have become increasingly popular in the construction industry, particularly for underground utilities. These pipes are designed to provide enhanced protection and durability while meeting the needs of various applications, including water supply, gas distribution, and telecommunications. By understanding the characteristics and benefits of plastic-coated steel pipes, professionals in the construction and decoration materials sector can make informed decisions for their projects.

One of the primary advantages of plastic-coated steel pipes is their ability to resist corrosion. The plastic coating acts as a barrier, protecting the underlying steel from moisture, soil particles, and chemicals that can lead to rust and degradation over time. This corrosion resistance is crucial in underground applications where pipes are constantly exposed to harsh environmental conditions. The longevity of these pipes means reduced maintenance costs and less frequent replacement, making them a cost-effective solution in the long run.

Additionally, the plastic coating provides a smooth surface that minimizes friction during fluid flow. This characteristic is particularly beneficial for water transportation systems, as it allows for greater efficiency and reduced energy consumption. The smooth interior of the pipes helps maintain water quality by preventing sediment build-up and bacterial growth, which can be a concern in traditional steel piping systems.

In terms of installation, plastic-coated steel pipes are relatively easy to handle and can be welded or joined using standard techniques. Their lightweight nature, when combined with the strength of steel, allows for efficient transportation and installation, reducing labor time and costs. Furthermore, the flexibility of these pipes enables them to adapt to various underground layouts and conditions, making them suitable for different utility projects.

When considering the environmental impact, plastic-coated steel pipes stand out as a sustainable choice. The materials used in the plastic coating are often recyclable, contributing to a circular economy in the construction industry. Moreover, their extended lifespan reduces the need for constant pipe replacements, thereby minimizing waste.

Regular inspection and maintenance are essential to ensure the longevity and performance of plastic-coated steel pipes. While the coating provides significant protection, it is still important to check for any signs of damage or wear that could compromise the integrity of the pipes. Implementing a proactive maintenance schedule can help identify potential issues early, ultimately protecting the investment in these materials.

In summary, plastic-coated steel pipes for underground utilities offer a range of benefits, including corrosion resistance, efficient fluid flow, ease of installation, and environmental sustainability. By integrating these pipes into their projects, construction professionals can enhance the durability and reliability of their infrastructure, ensuring a longer service life for underground utilities.

One of the primary advantages of plastic-coated steel pipes is their ability to resist corrosion. The plastic coating acts as a barrier, protecting the underlying steel from moisture, soil particles, and chemicals that can lead to rust and degradation over time. This corrosion resistance is crucial in underground applications where pipes are constantly exposed to harsh environmental conditions. The longevity of these pipes means reduced maintenance costs and less frequent replacement, making them a cost-effective solution in the long run.

Additionally, the plastic coating provides a smooth surface that minimizes friction during fluid flow. This characteristic is particularly beneficial for water transportation systems, as it allows for greater efficiency and reduced energy consumption. The smooth interior of the pipes helps maintain water quality by preventing sediment build-up and bacterial growth, which can be a concern in traditional steel piping systems.

In terms of installation, plastic-coated steel pipes are relatively easy to handle and can be welded or joined using standard techniques. Their lightweight nature, when combined with the strength of steel, allows for efficient transportation and installation, reducing labor time and costs. Furthermore, the flexibility of these pipes enables them to adapt to various underground layouts and conditions, making them suitable for different utility projects.

When considering the environmental impact, plastic-coated steel pipes stand out as a sustainable choice. The materials used in the plastic coating are often recyclable, contributing to a circular economy in the construction industry. Moreover, their extended lifespan reduces the need for constant pipe replacements, thereby minimizing waste.

Regular inspection and maintenance are essential to ensure the longevity and performance of plastic-coated steel pipes. While the coating provides significant protection, it is still important to check for any signs of damage or wear that could compromise the integrity of the pipes. Implementing a proactive maintenance schedule can help identify potential issues early, ultimately protecting the investment in these materials.

In summary, plastic-coated steel pipes for underground utilities offer a range of benefits, including corrosion resistance, efficient fluid flow, ease of installation, and environmental sustainability. By integrating these pipes into their projects, construction professionals can enhance the durability and reliability of their infrastructure, ensuring a longer service life for underground utilities.

TAG:

Related Posts

The Advantages of 3PE Fusion Bonded Epoxy Steel Pipe in Construction

3PE fusion bonded epoxy steel pipe is becoming increasingly popular in the construction and building materials industry, particularly for applications requiring robust and long-lasting piping solutions. The "3PE" in its name refers to a three-layer system consisting of an epoxy primer, a polyethylene (PE) outer layer, and a fusion bonded epoxy coating. This unique construction provides several sig