Exploring Corrosion Protection: The Role of Plastic-Coated Pipelines in Industrial Applications

Sep 24,2025

Exploring Corrosion Protection: The Role of Plastic-Coated Pipelines in Industrial Applications

Table of Contents

1. Introduction to Corrosion and Its Impact on Pipelines

2. Understanding Different Types of Corrosion

3. What Are Plastic-Coated Pipelines?

4. Benefits of Using Plastic-Coated Pipelines

4.1 Durability and Longevity

4.2 Cost-Effectiveness

4.3 Environment

Exploring Corrosion Protection: The Role of Plastic-Coated Pipelines in Industrial Applications

Table of Contents

- 1. Introduction to Corrosion and Its Impact on Pipelines

- 2. Understanding Different Types of Corrosion

- 3. What Are Plastic-Coated Pipelines?

- 4. Benefits of Using Plastic-Coated Pipelines

- 5. Applications of Plastic-Coated Pipelines in Various Industries

- 6. Installation and Maintenance of Plastic-Coated Pipelines

- 7. Future Trends in Corrosion Protection Technology

- 8. Conclusion

- 9. FAQs

1. Introduction to Corrosion and Its Impact on Pipelines

Corrosion is a natural process that leads to the deterioration of materials, particularly metals used in industrial pipelines. This phenomenon can significantly affect the operational efficiency and safety of various systems. **Understanding the implications of corrosion is crucial for industries** that rely heavily on pipelines for transporting fluids and gases. **The necessity for effective corrosion protection strategies** cannot be overstated, as the cost of corrosion-related failures can lead to significant financial losses and environmental hazards.

2. Understanding Different Types of Corrosion

Corrosion can manifest in several forms, each presenting unique challenges. Common types include:

2.1 Uniform Corrosion

Uniform corrosion occurs evenly across surfaces, often resulting in gradual material loss. It is common in environments where metals are exposed to moisture and air.

2.2 Pitting Corrosion

This localized form of corrosion leads to the formation of small cavities or pits on the surface of the material. It can be particularly dangerous, as it is often difficult to detect until significant damage has occurred.

2.3 Galvanic Corrosion

Galvanic corrosion occurs when two dissimilar metals come into contact in the presence of an electrolyte, leading to accelerated corrosion of one metal.

3. What Are Plastic-Coated Pipelines?

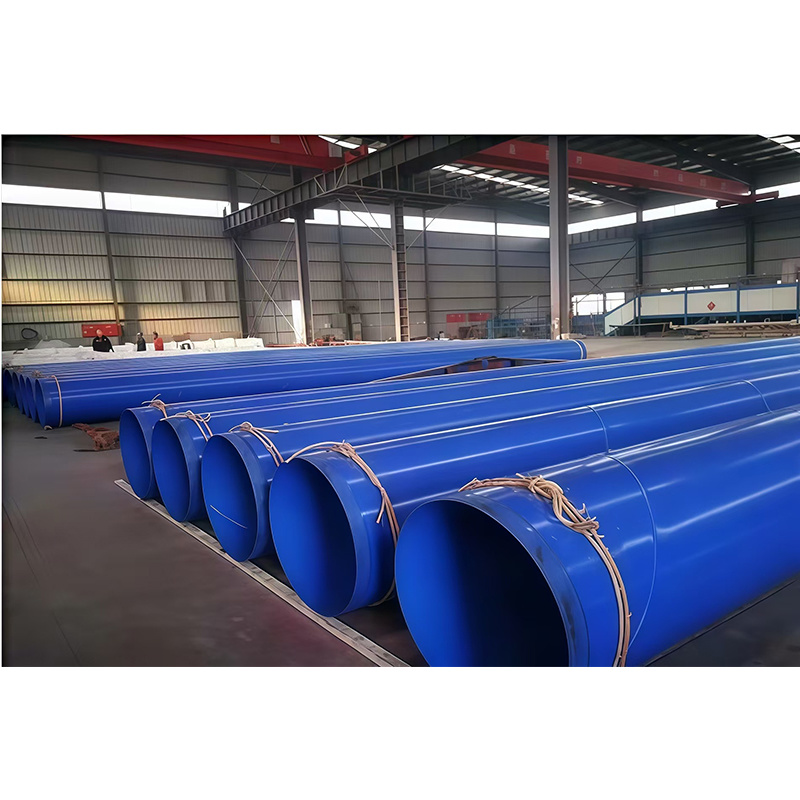

Plastic-coated pipelines are metal pipes that have been coated with a layer of plastic, typically polyethylene or polyvinyl chloride (PVC), to provide a barrier against corrosive elements. This protective coating is applied through various methods, including extrusion and dipping, which ensures a uniform and durable finish.

4. Benefits of Using Plastic-Coated Pipelines

Plastic-coated pipelines offer numerous benefits that make them an attractive option for industries seeking corrosion protection.

4.1 Durability and Longevity

The primary advantage of plastic-coated pipelines is their enhanced durability. The plastic layer protects the metal substrate from harsh environmental conditions, reducing the risk of corrosion and extending the lifespan of the pipeline. This durability translates to **lower maintenance costs** and fewer replacements over time.

4.2 Cost-Effectiveness

Implementing plastic-coated pipelines can be a cost-effective solution in the long run. While the initial investment may be higher than traditional pipelines, the reduced frequency of repairs and replacements can lead to significant savings over time. Industries can allocate resources more efficiently by minimizing downtime caused by corrosion-related issues.

4.3 Environmental Impact

Plastic-coated pipelines contribute to environmental sustainability. By preventing leaks and spills, these pipelines help protect ecosystems from contamination. Furthermore, the longevity of plastic-coated pipelines reduces the need for frequent replacements, leading to less waste and resource consumption.

5. Applications of Plastic-Coated Pipelines in Various Industries

Plastic-coated pipelines are versatile and can be utilized in various industries, including:

5.1 Oil and Gas Industry

In the oil and gas sector, pipelines are often exposed to corrosive substances and extreme environmental conditions. Plastic-coated pipelines provide the necessary protection to ensure safe and efficient transportation of hydrocarbons.

5.2 Water and Wastewater Management

Municipalities and industrial facilities rely on plastic-coated pipelines for water supply and wastewater management. The corrosion resistance of these pipelines ensures that water quality is maintained and that leaks are minimized.

5.3 Chemical Processing

The chemical industry frequently deals with aggressive chemicals that can corrode traditional pipelines. Plastic-coated pipelines offer a reliable solution for transporting various chemicals safely.

5.4 Food and Beverage Industry

In the food and beverage sector, hygiene and safety are paramount. Plastic-coated pipelines prevent corrosion and contamination, ensuring compliance with health regulations and maintaining product integrity.

6. Installation and Maintenance of Plastic-Coated Pipelines

Proper installation and maintenance are essential to ensure the longevity of plastic-coated pipelines.

6.1 Installation Process

The installation of plastic-coated pipelines requires skilled professionals to ensure that the coating is applied correctly and that the pipeline is securely positioned. Adhering to industry standards during installation helps prevent future issues related to improper placement or coating application.

6.2 Routine Maintenance

Although plastic-coated pipelines are designed for durability, routine inspections and maintenance are still necessary. Regular checks can identify any wear or damage to the plastic coating, allowing for timely repairs and extending the pipeline's lifespan.

7. Future Trends in Corrosion Protection Technology

As industries continue to innovate, several trends are emerging in corrosion protection technology.

7.1 Advanced Coating Materials

Research into new coating materials aims to enhance the protective qualities of plastic coatings. Innovations in nanotechnology and smart coatings could lead to even more effective corrosion prevention methods.

7.2 Sustainable Practices

The push for sustainability will drive the development of eco-friendly materials and practices in the production of pipelines. Industries will increasingly prioritize reducing their environmental footprint while maintaining operational efficiency.

7.3 Digital Monitoring Solutions

The integration of digital monitoring technologies will enable real-time tracking of pipeline integrity. These solutions can help detect corrosion early, allowing for proactive maintenance and reducing the risk of failure.

8. Conclusion

Plastic-coated pipelines play a crucial role in protecting industrial systems from corrosion, ensuring safe and efficient operations across various sectors. By understanding the benefits, applications, and maintenance requirements of these pipelines, industries can make informed decisions that enhance their infrastructure. As technology continues to evolve, the future of corrosion protection will likely bring even more innovative solutions to meet the demands of modern industries.

9. FAQs

What are the primary benefits of plastic-coated pipelines?

Plastic-coated pipelines offer enhanced durability, cost-effectiveness, and reduced environmental impact due to their corrosion-resistant properties.

How are plastic coatings applied to pipelines?

Plastic coatings can be applied through methods such as extrusion and dipping, ensuring a uniform and durable protective layer.

In which industries are plastic-coated pipelines commonly used?

Plastic-coated pipelines are widely used in the oil and gas, water and wastewater management, chemical processing, and food and beverage industries.

What maintenance is required for plastic-coated pipelines?

Routine inspections are essential to identify wear or damage to the coating. Timely repairs can help maintain the pipeline's integrity and longevity.

What trends are shaping the future of corrosion protection technology?

Emerging trends include the development of advanced coating materials, sustainable practices, and digital monitoring solutions for real-time tracking of pipeline integrity.

TAG:

Related Posts

The Advantages of 3PE Fusion Bonded Epoxy Steel Pipe in Construction

3PE fusion bonded epoxy steel pipe is becoming increasingly popular in the construction and building materials industry, particularly for applications requiring robust and long-lasting piping solutions. The "3PE" in its name refers to a three-layer system consisting of an epoxy primer, a polyethylene (PE) outer layer, and a fusion bonded epoxy coating. This unique construction provides several sig