The Advantages of 3PE Fusion Bonded Epoxy Steel Pipe in Construction

Sep 27,2025

3PE fusion bonded epoxy steel pipe is becoming increasingly popular in the construction and building materials industry, particularly for applications requiring robust and long-lasting piping solutions. The "3PE" in its name refers to a three-layer system consisting of an epoxy primer, a polyethylene (PE) outer layer, and a fusion bonded epoxy coating. This unique construction provides several sig

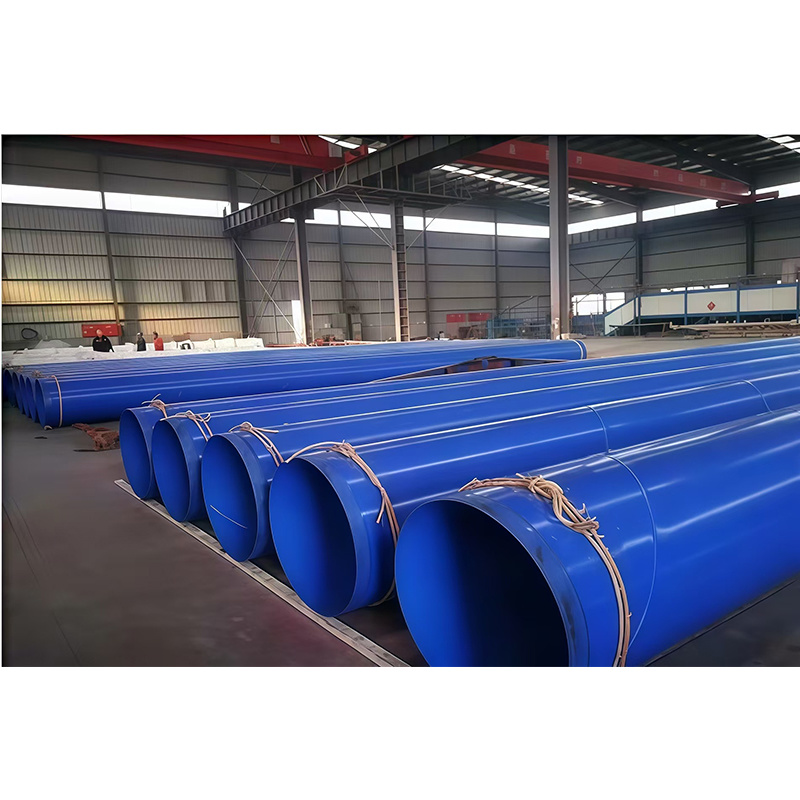

3PE fusion bonded epoxy steel pipe is becoming increasingly popular in the construction and building materials industry, particularly for applications requiring robust and long-lasting piping solutions. The "3PE" in its name refers to a three-layer system consisting of an epoxy primer, a polyethylene (PE) outer layer, and a fusion bonded epoxy coating. This unique construction provides several significant advantages over traditional piping materials.

One of the primary benefits of 3PE fusion bonded epoxy steel pipe is its exceptional corrosion resistance. The inner epoxy layer serves as a protective barrier against moisture, chemicals, and other corrosive agents that can lead to pipe degradation over time. By preventing rust and corrosion, these pipes maintain their structural integrity and performance, making them an ideal choice for projects that involve harsh environmental conditions, such as underground installations or chemical processing plants.

In addition to corrosion resistance, the 3PE fusion bonded epoxy steel pipe offers increased mechanical strength. Steel is known for its high tensile and compressive strength, and when combined with the protective layers, it becomes even more resilient against physical stresses. This robust nature allows for the safe transportation of water, gas, and other fluids without the risk of pipe failure, ensuring the reliability of the systems in which they are utilized.

Another important advantage of 3PE fusion bonded epoxy steel pipe is its long service life. The protective coatings not only enhance the pipe's durability but also reduce the need for frequent maintenance or replacement. This longevity translates into lower lifecycle costs for construction projects, making it a cost-effective solution in the long run.

Furthermore, the installation of 3PE fusion bonded epoxy steel pipes is relatively straightforward, which can save time and labor costs on construction sites. The lightweight nature of the PE layer can also facilitate easier handling and transportation, allowing for more efficient project execution.

When considering the environmental impact, the use of 3PE fusion bonded epoxy steel pipes can be beneficial as well. Their longevity and durability contribute to reduced waste generated from frequent replacements. Additionally, the production processes for these pipes can be designed to minimize ecological footprints, aligning with modern sustainable construction practices.

In conclusion, 3PE fusion bonded epoxy steel pipes offer a myriad of advantages for the construction industry. Their corrosion resistance, mechanical strength, and long service life make them a wise investment for projects that demand durability and reliability. As the construction sector continues to evolve, integrating such innovative materials can lead to more efficient and sustainable building practices. Whether for water transportation, gas distribution, or industrial applications, these pipes provide a practical solution that meets the rigorous demands of modern construction.

One of the primary benefits of 3PE fusion bonded epoxy steel pipe is its exceptional corrosion resistance. The inner epoxy layer serves as a protective barrier against moisture, chemicals, and other corrosive agents that can lead to pipe degradation over time. By preventing rust and corrosion, these pipes maintain their structural integrity and performance, making them an ideal choice for projects that involve harsh environmental conditions, such as underground installations or chemical processing plants.

In addition to corrosion resistance, the 3PE fusion bonded epoxy steel pipe offers increased mechanical strength. Steel is known for its high tensile and compressive strength, and when combined with the protective layers, it becomes even more resilient against physical stresses. This robust nature allows for the safe transportation of water, gas, and other fluids without the risk of pipe failure, ensuring the reliability of the systems in which they are utilized.

Another important advantage of 3PE fusion bonded epoxy steel pipe is its long service life. The protective coatings not only enhance the pipe's durability but also reduce the need for frequent maintenance or replacement. This longevity translates into lower lifecycle costs for construction projects, making it a cost-effective solution in the long run.

Furthermore, the installation of 3PE fusion bonded epoxy steel pipes is relatively straightforward, which can save time and labor costs on construction sites. The lightweight nature of the PE layer can also facilitate easier handling and transportation, allowing for more efficient project execution.

When considering the environmental impact, the use of 3PE fusion bonded epoxy steel pipes can be beneficial as well. Their longevity and durability contribute to reduced waste generated from frequent replacements. Additionally, the production processes for these pipes can be designed to minimize ecological footprints, aligning with modern sustainable construction practices.

In conclusion, 3PE fusion bonded epoxy steel pipes offer a myriad of advantages for the construction industry. Their corrosion resistance, mechanical strength, and long service life make them a wise investment for projects that demand durability and reliability. As the construction sector continues to evolve, integrating such innovative materials can lead to more efficient and sustainable building practices. Whether for water transportation, gas distribution, or industrial applications, these pipes provide a practical solution that meets the rigorous demands of modern construction.

TAG:

Previous

Related Posts

The Advantages of 3PE Fusion Bonded Epoxy Steel Pipe in Construction

3PE fusion bonded epoxy steel pipe is becoming increasingly popular in the construction and building materials industry, particularly for applications requiring robust and long-lasting piping solutions. The "3PE" in its name refers to a three-layer system consisting of an epoxy primer, a polyethylene (PE) outer layer, and a fusion bonded epoxy coating. This unique construction provides several sig